In the ever-evolving world of business, change is inevitable. Whether it’s driven by shifting market demands, rising costs, or quality concerns, the need to switch suppliers is a reality that many companies eventually face. However, transitioning to a new supplier can be a daunting process, often fraught with the risk of disrupting your supply chain. Fortunately, with careful planning and strategic execution, this transition can be managed smoothly and efficiently.

At Importivity, we specialize in guiding businesses through such transitions. By leveraging our expertise, we ensure minimal disruption while maintaining operational excellence every step of the way.

Understanding the Need for Supplier Transition

Before embarking on the journey of switching suppliers, it’s important to first understand the underlying reasons prompting this change. Typically, common motivations include:

- Cost Management: Rising costs can erode profit margins. If your current supplier’s pricing becomes unsustainable, seeking more cost-effective alternatives is prudent.

- Quality Concerns: Consistent quality issues can damage your brand’s reputation. A new supplier might offer superior quality control measures.

- Capacity Constraints: As your business grows, your supplier must scale accordingly. If they can’t keep up with your demand, it’s time to look elsewhere.

- Innovation and Technology: Staying competitive often requires the latest technologies. A supplier who invests in innovation can provide a significant advantage.

Recognizing these factors helps in making informed decisions and sets the foundation for a successful transition.

Steps to Ensure a Smooth Supplier Transition

Switching suppliers is not merely about selecting a new partner; it’s about ensuring that this change aligns with your business objectives without causing operational hiccups. Here’s a step-by-step guide to facilitate a seamless transition:

1. Conduct Thorough Due Diligence

To begin with, research potential suppliers thoroughly. Then, evaluate their financial stability, production capacity, quality control processes, and overall reputation within the industry. Additionally, engage with their existing clients to gain valuable insights into their performance and reliability before making a final decision.

2. Define Clear Expectations and Requirements

Next, clearly outline your expectations regarding product specifications, quality standards, delivery schedules, and communication protocols. Moreover, a detailed Service Level Agreement (SLA) can serve as a valuable reference point to ensure that both parties remain fully aligned throughout the partnership.

3. Develop a Transition Plan

In addition, a well-structured transition plan is essential for ensuring a seamless supplier switch. This plan should clearly outline timelines, key milestones, risk assessments, and contingency strategies. Furthermore, collaborate closely with both your current and new suppliers to effectively coordinate the handover process and minimize potential disruptions.

4. Communicate Transparently

Moreover, open communication with all stakeholders, including internal teams, existing and new suppliers, as well as customers, is absolutely vital. After all, transparency helps manage expectations while also reducing the potential for misunderstandings throughout the transition process.

5. Monitor the Transition Closely

During the transition phase, it’s crucial to closely monitor all activities. To ensure accountability, implement key performance indicators (KPIs) that help track progress and quickly address any issues that arise. Additionally, conducting regular audits and quality checks will help maintain consistent standards throughout the process.

Potential Challenges and How to Overcome Them

Although a structured plan lays the groundwork for a smooth transition, being mindful of potential challenges further enables you to proactively address them before they escalate.

- Supply Chain Disruptions: Unexpected delays can occur. Mitigate this by maintaining safety stock and diversifying your supplier base.

- Cultural and Language Barriers: When dealing with international suppliers, cultural differences can pose challenges. Employing bilingual staff or translators can bridge communication gaps.

- Regulatory Compliance: Ensure the new supplier complies with all relevant regulations and standards to avoid legal complications.

- Integration of Systems: Aligning technological systems between your company and the new supplier is crucial for seamless operations. Invest in compatible platforms or integration solutions.

The Role of Importivity in Facilitating Supplier Transitions

Navigating the complexities of supplier transitions requires expertise and experience. Importivity offers comprehensive services to assist businesses in this endeavor:

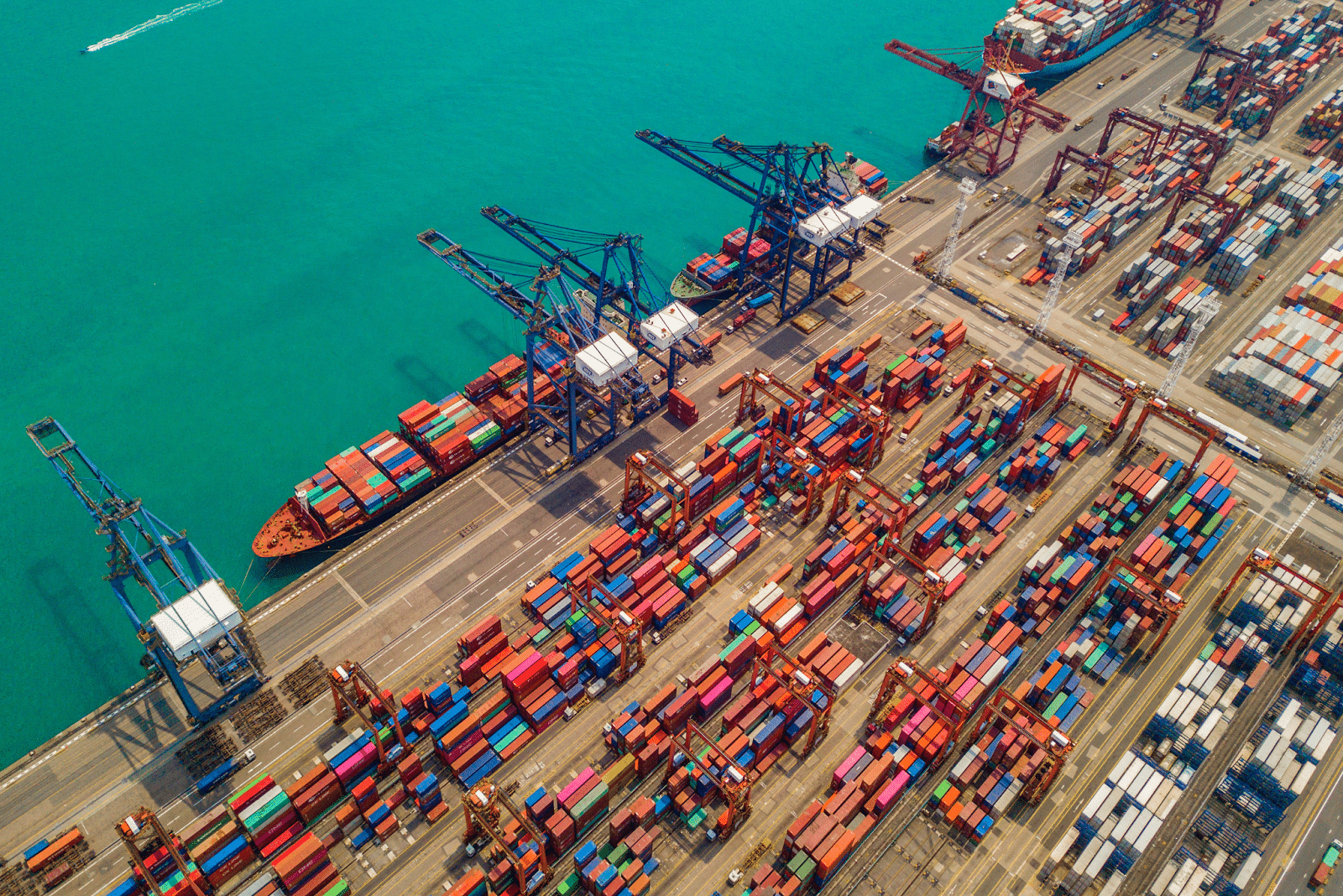

- Global Sourcing Solutions: With a vast network of vetted manufacturers across Vietnam, China, Mexico, and the United States, we connect you with suppliers that meet your specific needs.

- Supply Chain Management: Our team provides end-to-end supply chain management, ensuring that all aspects of the transition are handled efficiently.

- Import and Export Consulting: We offer expert guidance on regulatory compliance, tariffs, and logistics, simplifying the complexities of international trade.

- Manufacturer Reshoring: For businesses looking to bring manufacturing closer to home, we assist in re-establishing and optimizing relationships with domestic suppliers.

Ultimately, by partnering with Importivity, you leverage our expertise to ensure that your supplier transition is seamless while also aligning perfectly with your business objectives.

Takeaways

Undoubtedly, switching suppliers is a significant decision that can impact various facets of your business. However, with strategic planning, clear communication, and the right partners, this transition can lead to improved efficiency, cost savings, and enhanced product quality. At Importivity, we stand ready to support you through every step of this journey, ensuring that your supply chain remains robust, resilient, and future-ready.

For further insights and expert guidance on supply chain management and product sourcing, be sure to explore more resources from Importivity.

FREQUENTLY ASKED QUESTIONS

What is the first step in switching suppliers?

Start with thorough supplier research and due diligence to ensure they meet your quality, pricing, and reliability standards.

How can I prevent supply chain disruptions during a supplier switch?

Maintain buffer stock, create a transition plan, and coordinate closely with both the old and new suppliers to ensure a seamless shift.

What common mistakes should I avoid when changing suppliers?

Avoid rushing the process, failing to communicate with stakeholders, overlooking compliance requirements, and not testing the new supplier’s reliability.

How do I ensure quality control with a new supplier?

Conduct audits, request samples, establish clear quality standards, and implement regular performance monitoring.

Can Importivity help with supplier transitions?

Yes! Importivity provides expert supplier sourcing, risk mitigation, compliance support, and supply chain management for a smooth transition.