Sustainable packaging is no longer just an environmental buzzword; it has evolved into a strategic business choice that significantly impacts product sourcing costs. Across global supply chains, more companies are realizing that their packaging decisions directly affect transportation efficiency, product quality, regulatory compliance, and customer satisfaction. As a result, importers who once considered packaging an afterthought now treat it as a crucial element of cost control and sustainability.

At Importivity, we consistently observe this transformation. Businesses now understand that packaging is not merely an expense; it is a powerful tool that can either drain or enhance profitability. Through sustainable packaging, organizations are discovering ways to reduce hidden sourcing costs while improving their brand’s reputation and operational efficiency.

Why Sustainable Packaging Matters in Product Sourcing

In the past, packaging meant a simple box and tape. Today, however, it has become a calculated decision that influences freight charges, storage fees, and even environmental taxes. When importers plan their sourcing strategy, sustainable packaging must be viewed as an integral part of the process rather than the final step before delivery.

Eco-friendly packaging is typically lighter, more compact, and more durable. This means that when a company chooses sustainable materials and optimized designs, it not only reduces waste but also lowers shipping costs. Furthermore, better packaging design leads to fewer damaged goods, fewer returns, and greater overall efficiency. Consequently, sustainable packaging becomes both an environmental and a financial win.

The Hidden Costs of Traditional Packaging

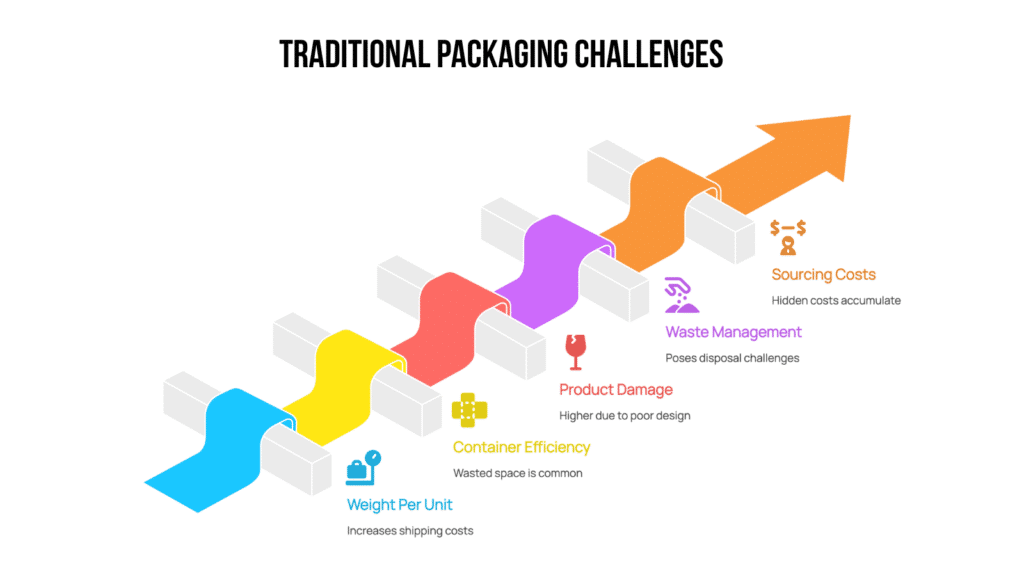

Traditional packaging often hides costs behind short-term savings.

- Wasted space: Bulky designs increase container usage.

- Higher weight: Standard plastic and heavy cardboard add shipping weight.

- Waste management: Customers face disposal challenges, and brands may face penalties in stricter markets.

While conventional packaging might seem cheaper upfront, it often conceals long-term expenses. Bulky or outdated materials can create multiple inefficiencies across the supply chain. For instance, heavy plastic and thick cardboard increase overall shipment weight, leading to higher freight bills. Similarly, oversized packaging wastes valuable container space, making logistics less efficient.

Traditional packaging also introduces disposal challenges for customers, particularly in regions where environmental regulations are strict. Non-recyclable materials can result in penalties or increased waste management costs. Over time, these issues accumulate and inflate sourcing expenses.

In contrast, sustainable packaging eliminates unnecessary weight, minimizes space, and supports recycling systems that reduce long-term waste. As companies transition toward greener options, they not only save money but also align themselves with international compliance standards and evolving consumer preferences.

Cost Benefits of Sustainable Packaging Sourcing

Choosing sustainable packaging sourcing is more than an ethical decision; it’s a financially smart one. When analyzed carefully, sustainable materials and designs consistently deliver measurable cost savings in several ways:

1. Lower transport fees

Lightweight materials reduce freight charges. For importers, this adds up quickly over large volumes.

2. Reduced damage

Eco-friendly packaging is often designed for durability. Less damage means fewer replacements and less wasted inventory.

3. Improved efficiency

Smart packaging designs use less space. This optimizes container loads and warehouse storage.

As shown, sustainable packaging sourcing helps balance efficiency and responsibility, directly influencing how businesses manage sourcing costs over time.

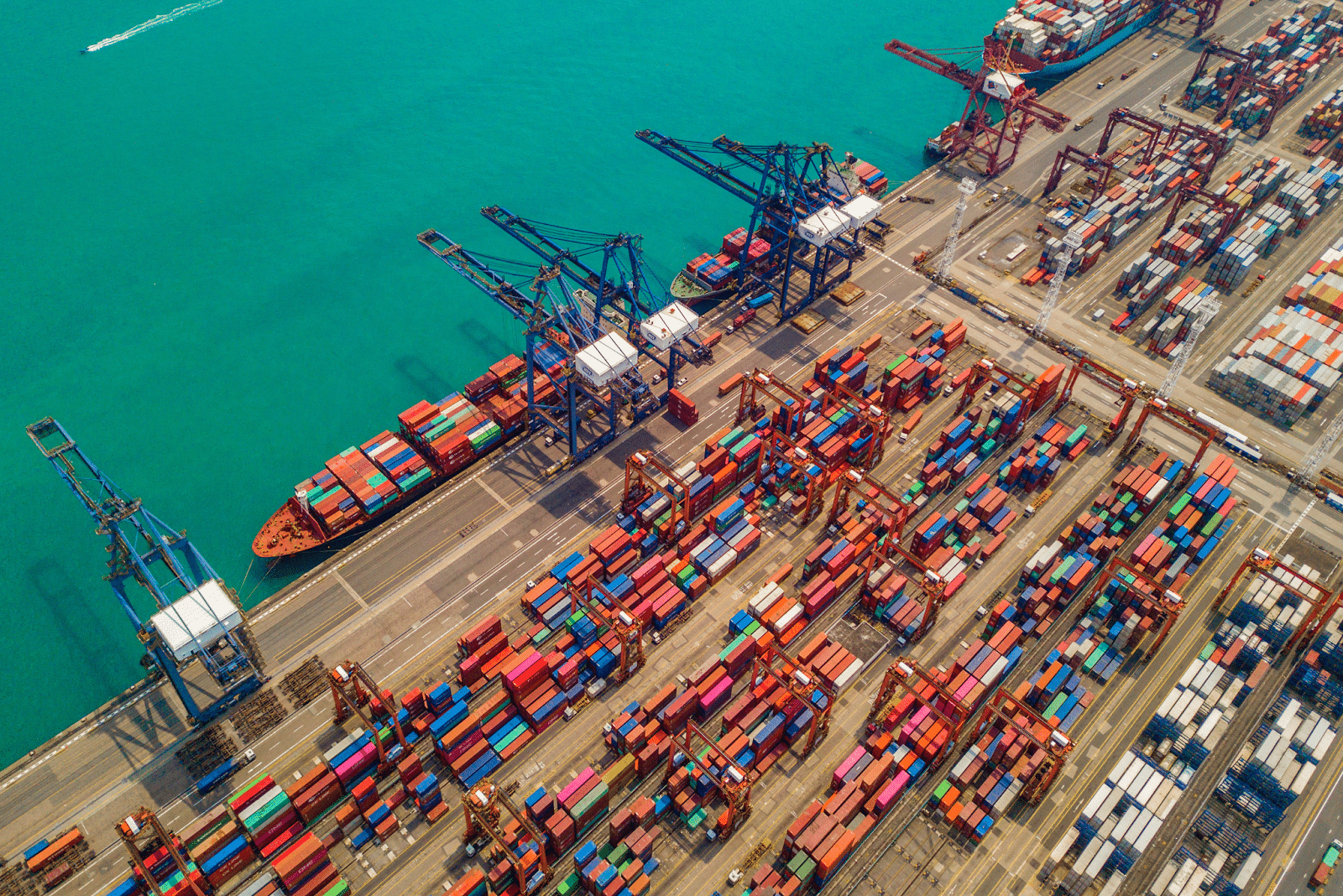

How Green Supply Chain Packaging Transforms Sourcing

Green supply chain packaging extends beyond recyclable boxes; it encompasses the entire product journey from supplier to customer. When importers implement sustainable packaging, they benefit from smoother customs procedures, stronger supplier relationships, and improved brand loyalty.

For instance, suppliers using recycled or renewable materials often experience fewer disruptions during raw material shortages. This stability ensures predictable sourcing costs, which is especially valuable during market fluctuations. Additionally, when every link in the chain prioritizes sustainability, the entire operation becomes more resilient.

Moreover, sustainable packaging enhances brand credibility. Businesses that demonstrate environmental responsibility not only attract eco-conscious customers but also enjoy positive relationships with regulators and stakeholders. This creates a long-term competitive advantage that extends beyond pricing alone.

Balancing Upfront Costs with Long-Term Savings

At first glance, sustainable packaging may appear more expensive due to biodegradable films, recycled fibers, and innovative designs. However, this perspective overlooks the full sourcing picture. When importers consider total landed costs—including shipping, returns, and penalties—sustainable packaging often proves to be more economical.

Companies investing in green materials experience:

- Lower freight charges

- Reduced return rates

- Fewer penalties for non-compliant packaging

- Better customer satisfaction scores

In essence, sustainable packaging sourcing pays for itself over time by delivering consistent operational efficiencies and improving overall business resilience.

The Customer Factor in Sustainable Packaging Decisions

Today’s consumers are not passive; they actively seek brands that align with their environmental values. Particularly in markets like Europe and North America, packaging choices can directly influence purchasing decisions and regulatory compliance.

Eco-friendly packaging is now a selling point. Customers are often willing to pay slightly more for products that reflect ethical sourcing and sustainability. This consumer loyalty helps brands reduce marketing costs and customer turnover. As trust grows, so does the willingness to remain loyal, even in competitive markets.

Therefore, sustainable packaging does more than protect goods, it strengthens customer relationships and brand reputation, creating a cycle of loyalty and long-term profitability.

Moreover, eco-friendly packaging for imports is no longer just a thoughtful extra; it has become a powerful selling point that can justify premium pricing. When customers recognize a brand’s commitment to sustainability, they are often more willing to remain loyal, even when prices increase slightly. Ultimately, that sustained loyalty helps reduce marketing expenses and lower customer churn, leading to stronger long-term profitability for the business.

Reducing Sourcing Costs with Sustainable Practices

Businesses aiming to cut costs through sustainable sourcing can take several practical steps.

1. Conduct a packaging audit.

Measure how much your current packaging contributes to container weight and space usage. Even small improvements can generate significant savings.

2. Partner with certified suppliers.

Choose suppliers that hold recognized sustainability certifications to avoid compliance issues and ensure long-term reliability.

3. Test durability and efficiency.

Sustainable packaging should be both protective and eco-friendly. Testing ensures your materials deliver both performance and sustainability.

4. Collaborate strategically.

Work closely with sourcing partners like Importivity to align supplier capabilities with your sustainability goals. Strategic collaboration ensures that your eco-friendly objectives remain cost-effective.

Through these steps, companies can unlock measurable savings while building a more responsible and efficient supply chain.

Real Success with Sustainable Packaging Sourcing

1. Consumer Electronics Importer

By switching from foam inserts to molded pulp packaging, this company achieved a 20% reduction in freight costs and 15% fewer damaged units, proving that eco-friendly solutions can be both practical and profitable.

2. Clothing Retailer

A shift to compostable mailers helped streamline customs clearance and elevate brand image. The retailer reported faster processing in eco-conscious regions and improved customer satisfaction.

3. Food Importer

By choosing lightweight biodegradable wraps, this business experienced lower air freight costs and reduced waste disposal fees. This decision not only cut costs but also strengthened brand sustainability credentials.

These examples demonstrate that sustainable packaging sourcing leads to real, quantifiable savings while reinforcing customer trust and operational efficiency.

The Future of Sustainable Product Sourcing Strategies

Sustainability is no longer optional; it is an expectation. Governments are tightening packaging regulations, while consumers are demanding transparency and environmental accountability. Businesses that delay adopting sustainable packaging risk facing penalties, increased costs, and reduced customer trust.

Conversely, those who embrace sustainable sourcing are better positioned for long-term growth. Their supply chains become more adaptable, their brand image improves, and their sourcing costs remain predictable even during global disruptions. In the future, sustainable packaging will be the foundation of every efficient sourcing strategy.

Ready to Start with Sustainable Packaging Sourcing?

If your goal is to reduce costs, strengthen your supply chain, and exceed customer expectations, now is the perfect time to transition toward sustainable packaging sourcing. Beyond compliance, it is about building smarter, cost-efficient operations that support both profitability and environmental responsibility.

At Importivity, we help businesses identify reliable, eco-conscious suppliers and implement sourcing strategies that balance cost and sustainability. By choosing sustainable packaging, your company can reduce waste, lower shipping expenses, and cultivate long-term customer trust, all while contributing to a greener planet.

Take the first step today. Discover how sustainable packaging sourcing can reshape your imports, optimize costs, and future-proof your business for success.

frequently asked questions

How does sustainable packaging sourcing reduce costs?

By lowering shipping weight, reducing damage, and improving efficiency in container usage.

Is eco-friendly packaging for imports more expensive?

Eco-friendly packaging for imports can look more expensive upfront, but in sourcing it often reduces costs by lowering freight fees, avoiding penalties, and reducing returns.

What is green supply chain packaging?

It refers to packaging choices that reduce environmental impact across the entire supply chain.

Can sustainable product sourcing strategies improve customer loyalty?

Yes, customers value eco-friendly practices and are more likely to stick with brands that show commitment.

How can businesses start reducing costs with sustainable sourcing?

Audit packaging, choose certified suppliers, and work with sourcing partners who prioritize sustainability.