Learn how transparent global sourcing budgeting prevents hidden costs and ensures smarter supplier partnerships.

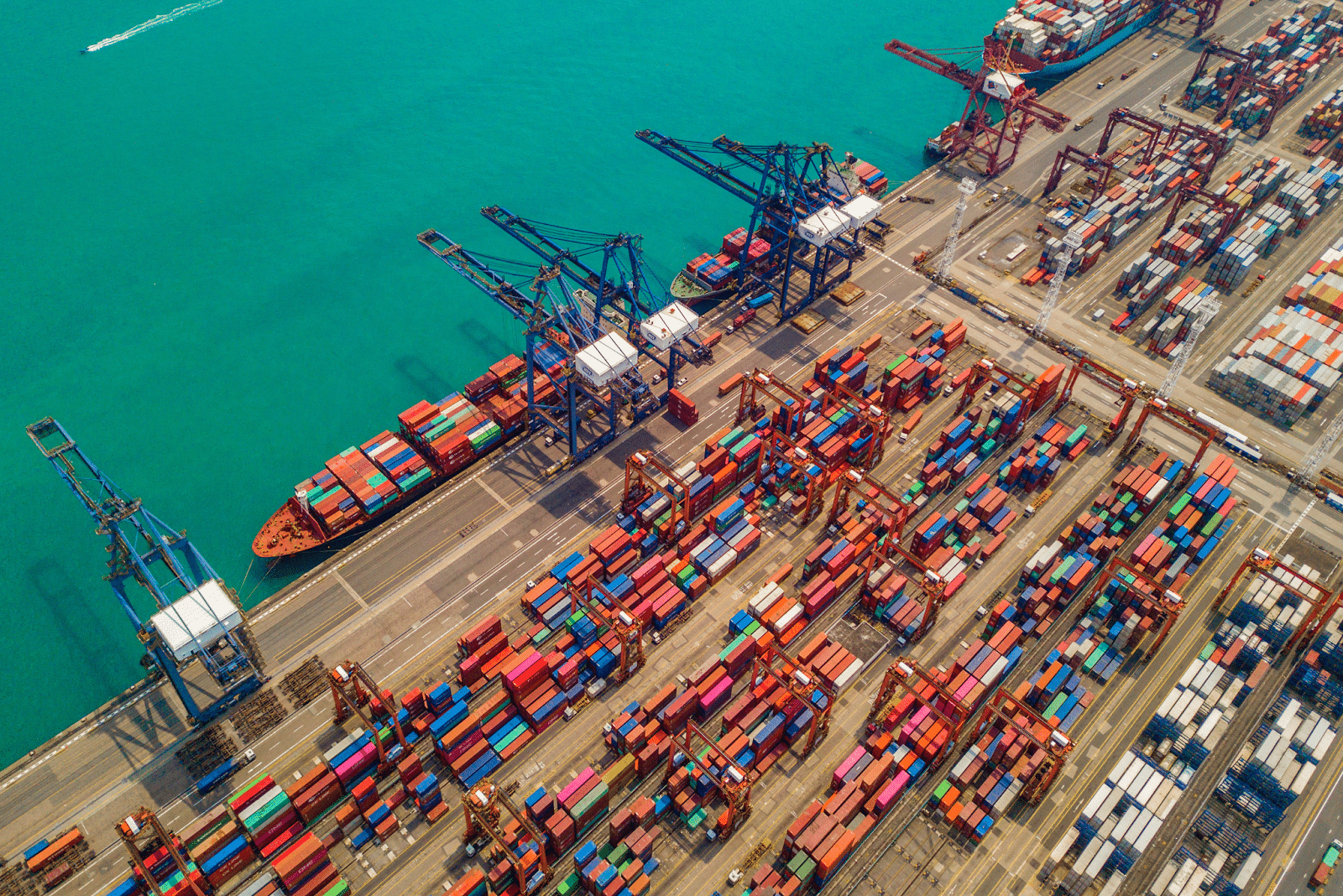

If you have ever tried sourcing products from overseas, you already know that it is rarely just about finding the lowest price. Global sourcing budgeting is about clarity. It means knowing not only what you are paying suppliers, but also where every dollar goes. Without that clarity, hidden costs in global sourcing can quickly eat into your margins and damage your trust with partners.

At Importivity, we have seen both sides. Businesses that plan with product sourcing cost transparency build stronger supplier relationships and keep projects on track. On the other hand, companies that skip detailed budget planning for imports often find themselves surprised by unplanned fees, inconsistent pricing, and delivery delays.

Why Transparent Budgeting is More Than Just Numbers

Budgeting is not just a spreadsheet. It is a conversation between you and your suppliers. A transparent approach makes it clear where the money goes, and it opens space for negotiation and trust.

For example, one client we worked with received a supplier quote that seemed competitive. When we broke it down, almost 15% of the total cost was hidden in “miscellaneous fees.” Once clarified, the supplier provided a proper supplier cost breakdown analysis, which not only reduced costs but also sped up production because both sides understood expectations.

This kind of openness saves money, but more importantly, it saves relationships.

Common Hidden Costs in Global Sourcing

When companies skip detailed analysis, the surprises add up. Here are some of the most common hidden costs in global sourcing:

Hidden Cost Category | What It Looks Like in Practice | Why It Matters |

Customs and Duties | Unexpected charges at the border | Delays and extra fees |

Quality Inspections | Separate billing for inspections | Can add up quickly |

Freight and Handling | Surcharges on top of shipping | Raises the final landed cost |

Supplier Add-Ons | “Processing fees” or vague charges | Hard to contest later |

Currency Fluctuations | Exchange rate changes | Impacts profit margin |

Understanding these costs through supplier cost breakdown analysis helps avoid being caught off guard.

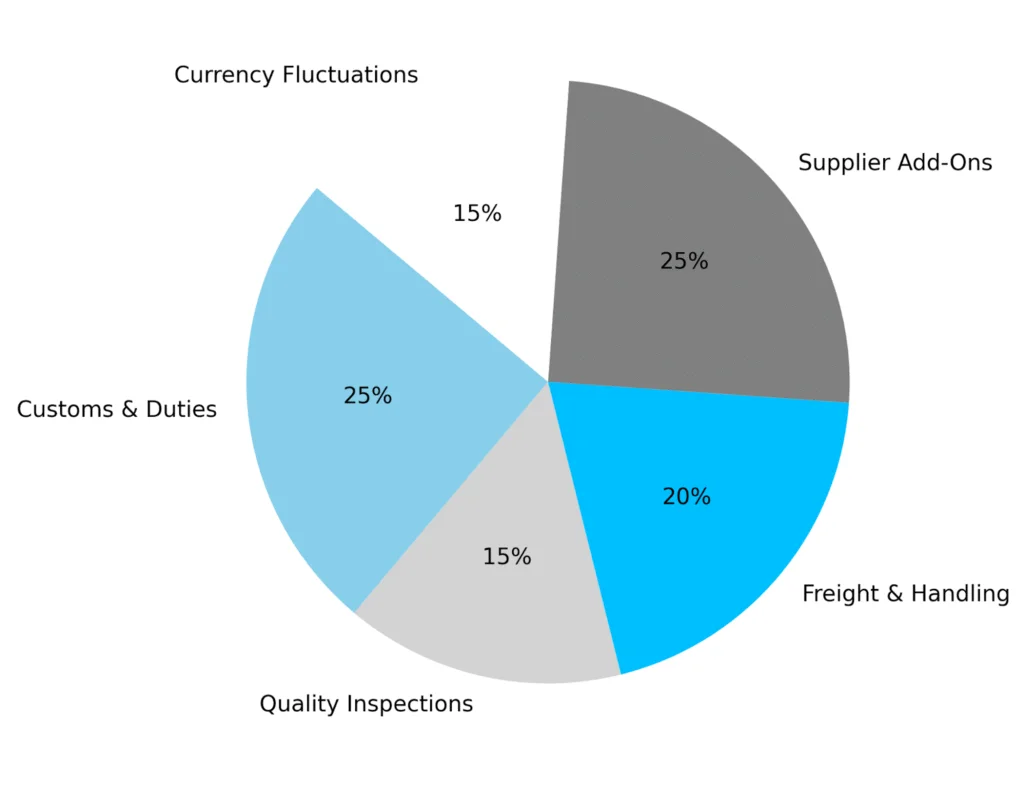

Visual Snapshot of Hidden Costs in Global Sourcing

Budget Planning for Imports: Why It Should Start Early

Budget planning for imports should not be a final step. It should be one of the first discussions with any supplier. When transparency is part of the early conversation, you can:

- Set realistic expectations for your team

- Compare suppliers fairly

- Negotiate from a stronger position

- Avoid production pauses caused by budget disputes

Transparent budgeting makes sure you do not have to scramble at the last minute.

Supplier Cost Breakdown Analysis: A Practical Example

Imagine two suppliers offer the same product at $5 per unit. At first glance, it seems like an easy decision. But with a closer look:

- Supplier A: $5 per unit, plus separate fees for packaging, inspection, and export documents.

- Supplier B: $5.40 per unit, all-inclusive with documentation, packaging, and inspection

Without a supplier cost breakdown analysis, you might choose Supplier A and end up paying more in the long run. Transparency helps you compare apples to apples.

How Global Sourcing Budgeting Builds Trust

Transparency is not only about avoiding surprises. It builds confidence. Suppliers respect clients who ask detailed questions because it signals seriousness. At the same time, clients feel confident when suppliers are willing to explain where each cost comes from.

In fact, some of the longest supplier partnerships we have seen began with clear budgeting conversations. Instead of focusing only on price, both sides worked together on cost-saving strategies, like adjusting packaging sizes or consolidating shipments.

Making Transparency a Habit

So how do you turn product sourcing cost transparency into a habit? Here are a few simple steps:

-

Always ask for detailed quotes

Break down every fee. If a supplier cannot explain, it is a red flag. -

Include inspections in your plan.

Whether done by a third party or the supplier, inspections have a cost. -

Plan for fluctuations

Exchange rates and seasonal freight prices shift. Build a cushion. -

Use technology for clarity.

Tools that compare supplier quotes side by side make gaps easier to spot. -

Document everything

Keeping records prevents disputes later.

These steps protect not just your finances but also your reputation.

Why Businesses Choose Professional Support

Handling global sourcing budgeting on your own can feel overwhelming, especially if you are juggling multiple suppliers and countries. Many businesses choose to work with professionals because it simplifies the process and ensures transparency from the start.

At Importivity, our product sourcing services include detailed cost analysis, supplier communication, and budget planning for imports. We make sure you are not left guessing about hidden costs.

Ready to Take Control of Your Global Sourcing Budget?

Transparent global sourcing budgeting is the key to avoiding hidden costs, building stronger supplier relationships, and keeping your projects on track. When you know exactly where your money is going, you stay in control.

Start your sourcing project with full cost transparency today. Contact Importivity now to plan your global sourcing budget with experts.

frequently asked questions

What is global sourcing budgeting, and why is it important?

It is the process of planning and clarifying all costs involved in sourcing products from other countries, including fees beyond supplier quotes.

Why does product sourcing cost transparency matter?

It helps avoid hidden costs and builds trust with suppliers by ensuring both sides know exactly what is included in the price.

What are examples of hidden costs in global sourcing?

Customs duties, inspection fees, freight surcharges, vague supplier add-ons, and exchange rate fluctuations are common hidden costs.

How do I compare suppliers fairly?

Ask for a supplier cost breakdown analysis so you can see what is included in the unit price and what is not.

When should I start budget planning for imports?

Start at the very beginning of supplier discussions. Waiting until production begins often leads to costly surprises.