When you’re sourcing products from overseas, the excitement of finding the perfect item at the right price can easily overshadow the risks. But here’s the truth: not every factory or distributor is who they say they are. That’s where the supplier vetting process becomes not just important but essential.

Think of it this way. You wouldn’t hire a new employee without checking their background, references, and skills. Why treat a potential supplier, someone who may handle thousands of dollars’ worth of your products, any differently? A single mistake can lead to delayed shipments, poor quality, or even total financial loss.

Let’s break down why supplier vetting matters so much and how it saves you from costly mistakes.

What is the Supplier Vetting Process?

- At its core, vetting involves:

- Overseas supplier verification: confirming that the business is real, registered, and legally operating.

- Supplier background checks: looking at ownership records, financial history, and any red flags such as lawsuits or blacklisting.

- Reliable manufacturer selection: testing capacity, quality standards, and consistency.

- Without these checks, you’re essentially sending money overseas on blind faith.

The Risks of Skipping Supplier Vetting

1. Fraud and Scams

Unfortunately, overseas sourcing has its share of fake suppliers. They might operate slick websites, send convincing quotes, and then disappear after receiving payment. Verification helps you avoid falling victim.

2. Poor Quality Products

Even legitimate suppliers can cut corners. Without proper checks, you could end up with substandard goods that damage your brand reputation.

3. Production Delays

Some factories accept more orders than they can handle. Others outsource to unknown subcontractors. Both can lead to serious delays, which can ruin your sales cycle.

4. Compliance Issues

Importing isn’t just about getting products delivered. Products must meet local regulations, safety standards, and certifications. A reliable vetting process ensures compliance before goods even leave the factory.

5. Hidden Costs

How Overseas Supplier Verification Works

Let’s say you’ve found a supplier in China, India, or Vietnam. How do you know they’re legitimate?

Verification usually includes:

- Checking registration documents with local authorities.

- Reviewing export licenses and compliance certifications.

- Investigating the physical location, either through third-party site audits or on-the-ground visits.

- Speaking directly with past clients or partners.

This level of overseas supplier verification gives you confidence that the company is real, stable, and not just a name in your inbox.

Reliable Manufacturer Selection: More Than Just Price

- Reliable manufacturer selection involves looking deeper:

- Can they handle your order volume consistently?

- Do they follow international quality standards like ISO certifications?

- Have they demonstrated transparency in their supply chain?

Choosing reliability over price helps with long-term partnerships, consistent product quality, and reduced risk.

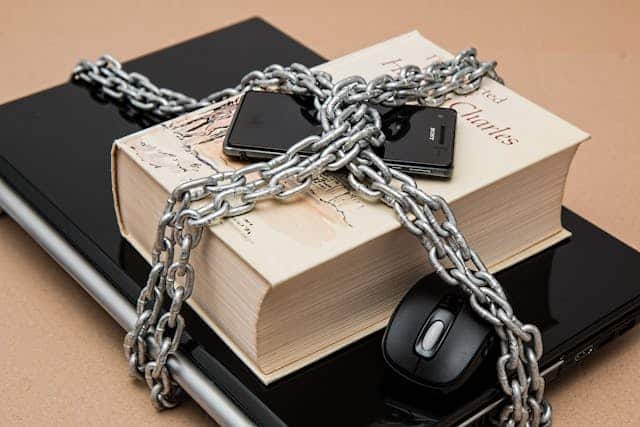

Why Supplier Background Checks Matter

Imagine discovering after signing a contract that your supplier has been blacklisted for labor violations, or that their factory shut down last year and they’re now outsourcing to unknown third parties.

- Supplier background checks are your safeguard. They can reveal:

- Ownership disputes

- History of late deliveries

- Quality complaints from previous buyers

- Legal or compliance issues

With this knowledge, you avoid tying your business to a risky partner.

Risk Reduction in Sourcing: The Bigger Picture

- The main goal of the supplier vetting process is risk reduction in sourcing. By carefully verifying suppliers, you:

- Protect your investment.

- Secure consistent product quality.

- Build long-term trust.

- Ensure compliance with international trade laws.

In short, it’s not just about avoiding problems. It’s about creating a stable supply chain that supports growth.

Real-World Example

One of our clients came to us after a nightmare experience. They had paid an overseas supplier upfront, only to find that the “factory” was just a rented office with no production capacity. It took months to recover the loss, and they nearly missed their retail launch.

After going through a professional vetting process, they now work with a verified supplier who has delivered consistently for three years. The peace of mind that comes from verified trust is priceless.

How Importivity Helps with Supplier Vetting

At Importivity, we know that every shipment, every deadline, and every dollar matters. That’s why our supply chain management services include:

- Detailed overseas supplier verification

- Comprehensive supplier background checks

- Factory audits and quality inspections

- Ongoing monitoring of supplier performance

Instead of leaving things to chance, we make sure every step of your supply chain is transparent and secure.

Ready to Secure Your Supply Chain with Confidence?

Importing from overseas doesn’t have to feel like a gamble. With the right supplier vetting process in place, you can protect your investment, avoid costly mistakes, and build lasting partnerships with manufacturers you can trust.

At Importivity, we make sure you don’t have to take chances. From background checks to factory audits, our team ensures that every supplier you work with is verified, reliable, and aligned with your business goals.

Take the first step toward a safer, smarter supply chain today. Contact us here to learn how our supplier vetting and supply chain management services can protect your business and help it grow.

frequently asked questions

What is the supplier vetting process?

It is the evaluation system that checks if an overseas supplier is legitimate, reliable, and capable of meeting your requirements.

Why is overseas supplier verification important?

It confirms that your supplier is a registered business, reducing the risk of fraud and protecting your investment.

How do supplier background checks work?

They involve reviewing ownership records, financial health, compliance history, and customer feedback to identify red flags.

What happens if I skip supplier vetting?

You risk fraud, poor quality, delays, compliance failures, and hidden costs that could harm your business.

Can I manage supplier vetting myself?

While possible, professional vetting services provide deeper verification, access to local databases, and more reliable results.