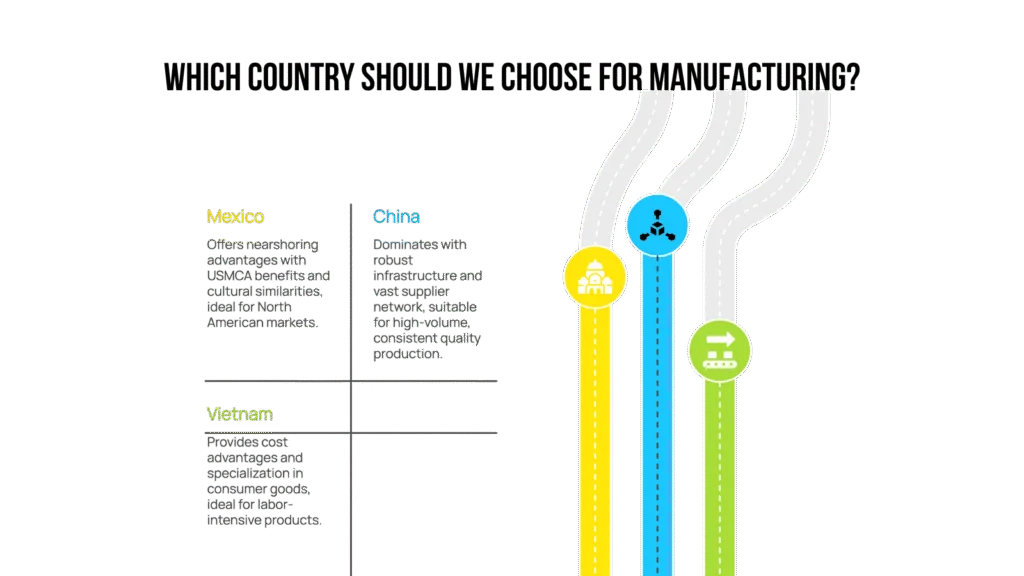

When businesses begin exploring sourcing from Vietnam, China, or Mexico, their initial focus often gravitates toward comparing prices, production speed, and reliability. However, successful sourcing goes far beyond just cost efficiency. Each of these regions offers unique advantages, trade dynamics, and operational challenges, making it essential for businesses to adopt a strategy that aligns their sourcing choices with long-term supply chain goals.

In fact, whether you are comparing China’s established industrial ecosystem with Vietnam’s rising potential or Mexico’s nearshoring convenience, your success will depend on making informed choices that match your product category, delivery requirements, and market positioning. Therefore, before selecting a country, it is crucial to assess the broader strategic implications that affect not just short-term gains but also long-term scalability and flexibility.

Why Businesses Are Expanding Beyond China

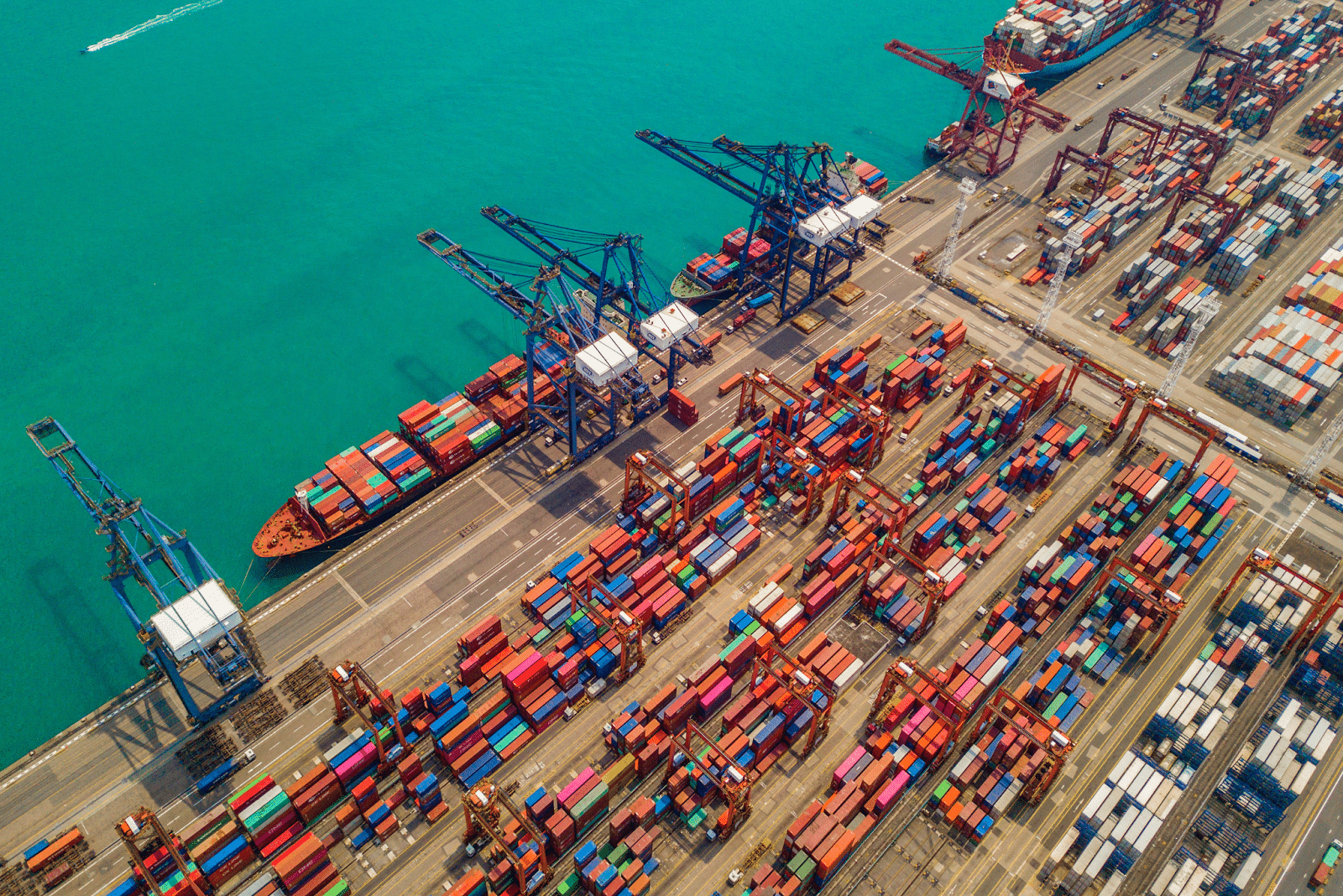

For decades, China has remained the leading choice for global sourcing, offering unparalleled scale, sophisticated infrastructure, and a well-established supplier base. Yet, due to rising labor costs, increased tariffs, and recent supply chain disruptions, businesses worldwide are now rethinking their dependency on a single manufacturing hub.

Even though China continues to provide speed, expertise, and product diversity, more companies are turning their attention toward sourcing from Vietnam and Mexico as part of a diversified procurement strategy. By broadening their sourcing network, importers can mitigate risks related to geopolitical instability, pandemic-related disruptions, and fluctuating trade regulations.

Furthermore, diversifying supply chains not only reduces exposure to sudden interruptions but also encourages innovation, as manufacturers in emerging markets bring fresh ideas, sustainable practices, and competitive pricing models to the table.

The global spotlight is increasingly shifting toward sourcing from Vietnam, which has rapidly transformed into a major hub for manufacturing, particularly in apparel, electronics, and furniture. With its competitive labor costs, strategic trade partnerships, and expanding industrial base, Vietnam has become a vital alternative for businesses seeking both affordability and quality.

Sourcing from Vietnam & The Rising Manufacturing Powerhouse

Key Advantages of Importing from Vietnam

One of the primary reasons companies are sourcing from Vietnam is its cost efficiency. Labor rates are significantly lower than in China, which makes it ideal for labor-intensive production like textiles and footwear. Additionally, Vietnam has secured multiple free trade agreements, allowing businesses to enjoy tariff reductions and smoother cross-border transactions.

Beyond cost and trade benefits, Vietnam’s manufacturing sector is evolving rapidly. The country is advancing from traditional industries toward higher-value sectors such as consumer electronics, machinery, and precision parts, positioning itself as a long-term sourcing contender in the global arena.

Challenges to Consider When Sourcing from Vietnam

While the opportunities are vast, sourcing from Vietnam does come with challenges. Infrastructure improvements are ongoing, but logistics such as port efficiency and transportation can still lag behind more mature markets. Factories may also operate on a smaller scale, which can limit large-volume production capacity.

Moreover, maintaining consistent quality requires strong quality control mechanisms. Companies that thrive in Vietnam usually partner with local inspection teams or sourcing agents to ensure compliance with international standards and timelines.

Manufacturing in Mexico vs. China

With the growing emphasis on supply chain agility, Mexico has emerged as a highly strategic alternative, particularly for U.S. and Canadian businesses. Nearshoring reduces delivery times, lowers transportation costs, and facilitates real-time collaboration due to closer proximity and overlapping time zones.

Benefits of Sourcing from Mexico

Mexico’s location offers a clear logistical advantage for North American importers. The USMCA (United States–Mexico–Canada Agreement) provides reduced tariffs and improved trade facilitation. Additionally, cultural similarities and shared time zones simplify communication and project coordination.

However, while Mexico excels in automotive, aerospace, and heavy manufacturing, it may not yet match Vietnam’s strengths in consumer goods or China’s vast supply ecosystem. Labor costs are also slightly higher than in Vietnam, though still favorable compared to the U.S.

When Mexico Might Not Be the Best Fit

- Product specialization: Mexico excels in automotive, aerospace, and heavy manufacturing but is less developed in consumer electronics.

- Higher labor costs: While lower than in the U.S., they are generally higher than in Vietnam.

- Supplier network: Smaller compared to China’s vast ecosystem.

To see practical examples of Mexico sourcing, check out our Mexico manufacturer connections.

Why China Still Dominates Global Sourcing in 2025

Despite global diversification trends, China’s dominance in manufacturing remains unshaken. Its robust infrastructure, advanced technology adoption, and vast supplier network make it an indispensable component of most global sourcing strategies.

China’s factories are not only capable of scaling production quickly but also have the technical expertise to deliver precision and consistency. While sourcing from Vietnam offers cost advantages, China’s mature ecosystem provides unmatched integration of materials, logistics, and innovation.

Businesses that maintain partnerships with Chinese suppliers benefit from well-established communication channels, efficient customs processes, and the ability to produce everything from low-cost goods to high-end electronics with consistent quality.

Building a Balanced Global Sourcing Strategy

Rather than choosing one country over another, forward-thinking companies are adopting blended sourcing models that combine the strengths of multiple regions. A hybrid approach involving sourcing from Vietnam, China, and Mexico enhances resilience, flexibility, and competitive advantage.

- Dual sourcing: Keep production in China for scale, but add Vietnam or Mexico for risk diversification.

- Nearshoring with backup: Utilize Mexico for expedited U.S. delivery and Vietnam as a cost-effective alternative for labor-intensive products.

- Category-specific sourcing: Apparel in Vietnam, heavy equipment in Mexico, electronics in China.

This balanced approach ensures that when trade policies shift or global disruptions occur, your operations remain agile and protected from dependency on a single market.

Supply Chain Risk Management & Key Questions to Ask

Before deciding between China, Mexico, or sourcing from Vietnam, companies should evaluate several critical factors:

- What is the total landed cost after tariffs, shipping, and duties?

- How stable is the supplier base in that region?

- Are you prioritizing cost, speed, or quality?

- Do you need consistent high-volume production or smaller, specialized orders?

- How important is proximity to your final market?

Answering these helps identify whether sourcing from Vietnam, China, or Mexico best matches your priorities.

Simplify Your Global Sourcing with Expert Support

At Importivity, we eliminate the guesswork from sourcing in Vietnam, China, or Mexico. Rather than spending months navigating unfamiliar suppliers, exchanging endless back-and-forth emails, and managing potential quality risks, we streamline the process by connecting you directly with vetted manufacturers that align with your specific product requirements and business objectives.

Moreover, whether you’re seeking the cost advantages of Vietnam, the logistical proximity of Mexico, or the unmatched scale of China, our team works alongside you to build a dependable, efficient, and stress-free supply chain. In doing so, we help you not only save time and resources but also gain a competitive edge in your global sourcing strategy.

Start your sourcing journey with Importivity today and get connected with manufacturers you can trust.

frequently asked questions

Is Vietnam cheaper than China for manufacturing?

Yes, labor costs are lower in Vietnam, making it cost-effective for textiles and consumer goods, though China offers more scale.

Why are companies moving manufacturing to Mexico?

Proximity to the U.S., shorter shipping times, and USMCA benefits make Mexico appealing, especially for nearshoring.

Can I still rely on China for sourcing?

Absolutely. China remains the most capable option for mass production and advanced manufacturing.

What are the risks of sourcing from Vietnam?

Infrastructure gaps, smaller supplier networks, and quality variability are the main challenges.

Should businesses split sourcing between multiple countries?

Yes, spreading production across Vietnam, China, and Mexico reduces risk and increases flexibility.