Switching suppliers supply chain strategies often come into play when businesses outgrow their current vendor or face recurring issues with pricing, quality, or delivery. But let’s be honest, changing a supplier can feel like rewiring your house while keeping the lights on. It’s risky, stressful, and if done wrong, it can bring production to a halt.

The good news? With a clear supplier transition strategy, you can minimize supply disruption and even strengthen your supply chain continuity in the long run. In this guide, we’ll walk through what to expect, how to prepare, and the exact steps to take for a smooth vendor change process.

Why Businesses Consider Switching Suppliers

- Before we talk about how to change, let’s address the why. Companies typically start considering a supplier transition when they experience:

- Consistent delays in delivery that throw off production schedules

- Escalating costs without added value

- Quality issues that hurt customer trust

- Limited capacity as your business scales

- Poor communication that leaves you in the dark during disruptions

If any of these feel familiar, you’re not alone. Many businesses face this exact crossroad, where staying with the current vendor feels just as risky as moving on.

Key Risks of Switching Suppliers Supply Chain

- Switching isn’t just about signing a new contract. It comes with potential pitfalls:

- Supply disruption: Any hiccup during the change can stall production.

- Learning curve: Your new supplier may need time to fully understand your processes.

- Hidden costs: Transitioning often involves onboarding, system updates, and training.

- Relationship strain: If the old supplier is still part of your network, tensions may rise.

Acknowledging these risks upfront allows you to create a realistic supplier transition strategy.

Step 1: Map Out a Supplier Transition Strategy

- Think of this as your playbook. A well-prepared plan outlines:

- 1. Objectives: Why are you switching? Lower cost? Better quality? Faster lead times?

- 2. Selection criteria: Define what your new supplier must deliver on day one.

- 3. Timeline: Create a phased approach instead of a sudden cut-off.

- 4. Contingency plans: If the new supplier struggles, what’s your backup?

For deeper support, Importivity offers supply chain management services that include hands-on transition planning.

Step 2: Evaluate the Impact on Supply Chain Continuity

Every supplier transition touches multiple layers of your operations. To minimize supply disruption, look at:

- Production schedules: Will the switch cause downtime?

- Inventory levels: Do you need buffer stock during the transition?

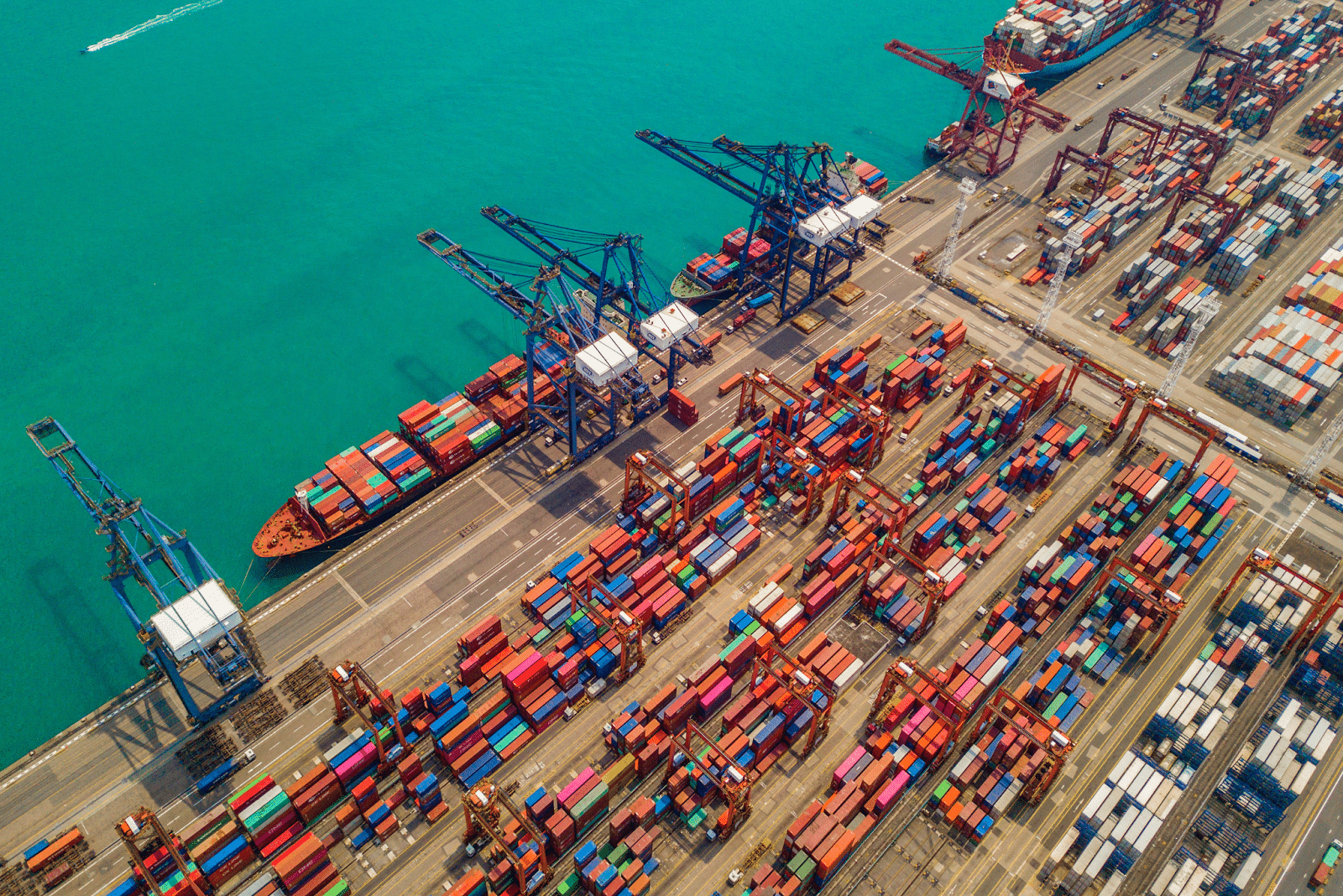

- Shipping routes: Does the new supplier ship from the same region?

- Technology systems: Can their ordering system integrate with yours?

This evaluation keeps surprises to a minimum and ensures a smooth vendor change process.

Step 3: Build a Strong Onboarding Process

- Your new supplier isn’t a plug-and-play solution. They need onboarding. That includes:

- Sharing your technical specifications in detail

- Training their team on your compliance standards

- Testing sample orders before full-scale production

- Establishing clear communication channels

This step is where many businesses go wrong. They rush to switch without ensuring the supplier can actually meet day-to-day expectations

Step 4: Keep the Old Supplier in the Loop

Even if you’re moving on, it’s smart to manage the exit gracefully. Why? Because until your new vendor is fully reliable, your old supplier may still serve as a backup. Keep the conversation professional and transparent. Burning bridges creates unnecessary risk.

Step 5: Monitor and Adjust During the Transition

- Once you flip the switch, you’re not done. Expect a three-to-six-month adjustment period. Use this time to:

- Track key metrics like delivery times, order accuracy, and defect rates

- Hold weekly check-ins with the new supplier

- Collect feedback from your internal team

- Fine-tune processes where gaps appear

By treating the first few months as a trial phase, you can strengthen long-term supply chain continuity.

A Practical Look: Transition Timeline Example

Here’s how a realistic supplier transition strategy might unfold:

Phase | Duration | Key Actions | Goal |

Planning | 4 weeks | Define objectives, select new supplier, build contingency plan | Avoid surprises |

Preparation | 6 weeks | Onboard supplier, run sample orders, stock buffer inventory | Reduce risk |

Transition | 8 weeks | Shift partial orders, monitor performance, keep old supplier active | Smooth vendor change process |

Stabilization | 12 weeks | Fully transition, refine systems, review supplier scorecard | Secure supply chain continuity |

How to Minimize Supply Disruption During a Switch

- Some real-world tactics that work:

- Dual sourcing: Run both suppliers in parallel for a short period

- Buffer stock: Hold extra inventory to cover possible delays

- Clear documentation: Standard operating procedures reduce misunderstandings

- Transparent communication: Keep your entire team aligned with regular updates

These aren’t theoretical, they’re practices that companies have used successfully to move suppliers without upsetting production.

Internal Communication Matters

A supplier change isn’t just about contracts and logistics. Your employees need clarity too. Keep departments informed about timelines, potential risks, and expected improvements. That way, if there’s a hiccup, no one is caught off guard.

When to Get Outside Help

Sometimes, managing the switch in-house adds unnecessary stress. If your supply chain is global or your production is complex, it may be smarter to partner with experts. Firms like Importivity specialize in minimizing supply disruption through structured transition planning and vendor management.

You can contact Importivity here if you’re considering switching suppliers supply chain strategies and want support in making it seamless.

Expect Challenges, But Plan for Continuity

Switching suppliers doesn’t have to mean chaos. Yes, there will be challenges, but with the right supplier transition strategy you can keep your supply chain continuity intact while even improving performance over the long term. The key is preparation, clear communication, and ongoing monitoring.

The end result? A smoother vendor change process that not only minimizes supply disruption but also sets your business up for future growth.

frequently asked questions

How long does it usually take to switch suppliers without disruption?

On average, three to six months is needed to fully stabilize after a switch.

What’s the biggest risk during a supplier transition?

The most common risk is supply disruption due to misaligned processes or miscommunication.

Should I keep working with my old supplier during the switch?

Yes, many businesses run both suppliers in parallel until the new one proves reliable.

How can I minimize supply disruption during the switch?

Strategies include dual sourcing, buffer stock, and detailed onboarding.

Is switching suppliers always a bad idea?

Not at all. Done strategically, it can actually strengthen your supply chain in the long run.