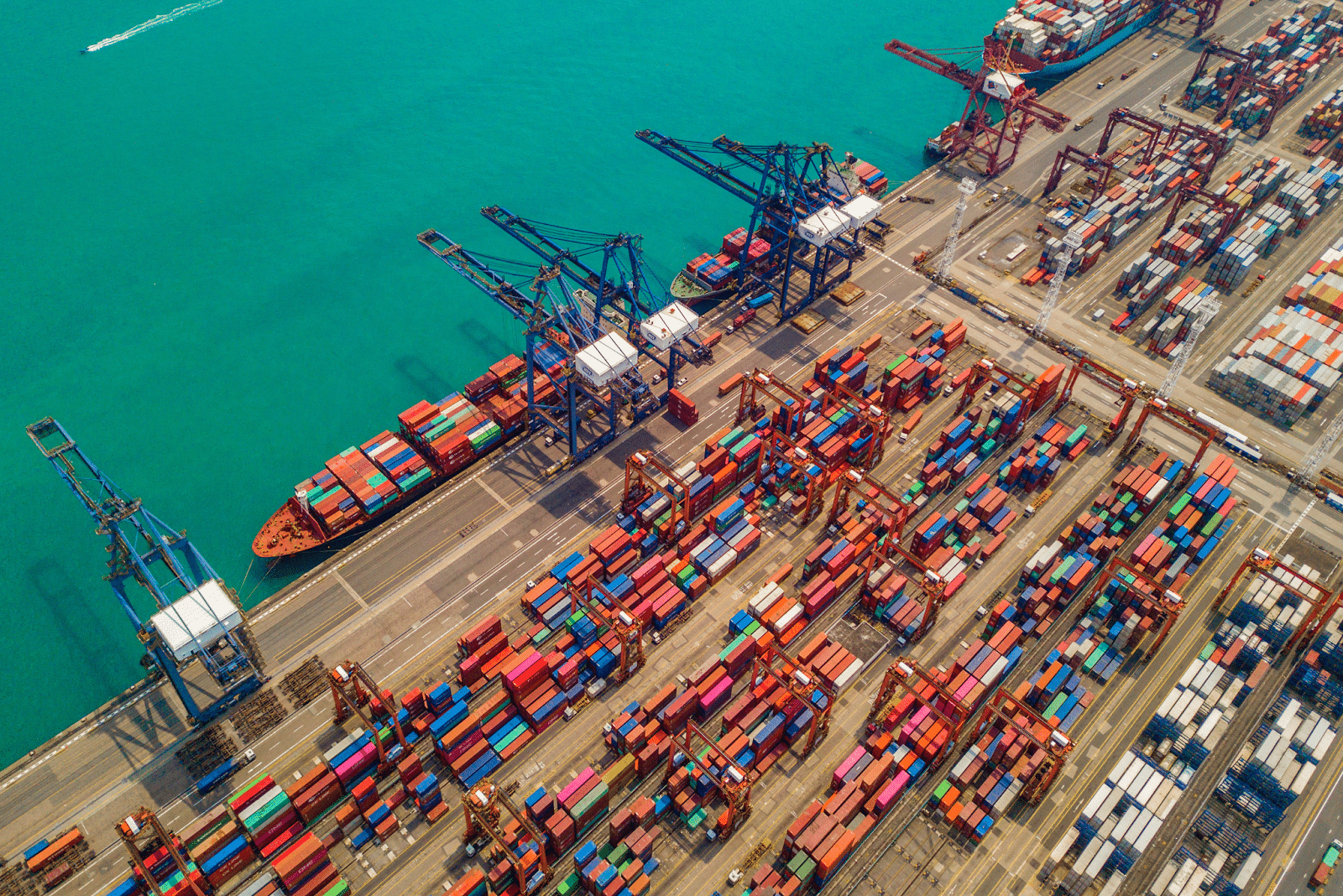

If you have ever worked with an overseas factory, you know the risks. A shipment can look great in photos, but when the products land at your warehouse, you suddenly find misprints, broken stitching, or electronics that stop working after one use. These quality control issues don’t just hurt your bottom line. They damage trust with your customers and slow down your business growth.

The good news is that you can stay ahead of these problems. With the right steps, such as factory audits, third-party inspections, and consistent follow-up, you can avoid defective imports and maintain consistent product quality assurance even when your production is thousands of miles away.

Step 1: Start with the right factory partnership

The first layer of avoiding quality control issues is choosing the right partner. It might sound obvious, but many importers still pick a factory based on low pricing alone. A cheaper unit cost is meaningless if half the products arrive defective.

- When evaluating potential factories, consider:

- Their history of exports and whether they regularly work with your target market.

- Certification checks, such as ISO or industry-specific standards.

- Client references or verifiable reviews from importers like you.

This is where factory audits become essential. A professional audit team visits the factory, reviews production capacity, checks compliance documents, and evaluates working conditions. Without this step, you’re guessing. With it, you’re building on verified facts.

Step 2: Put agreements in writing

Factories often work with multiple clients at the same time. Without clear agreements, your product specifications may not always receive top priority. Misunderstandings here are one of the most common causes of quality control issues.

- What to include in your purchase agreements:

- Exact material specifications

- Packaging requirements

- Tolerances for size, weight, and finish

- Delivery timelines and penalties for delays

If these expectations are only discussed verbally, you are inviting problems later. A signed document gives you leverage and keeps expectations consistent.

Step 3: Don’t skip third-party inspections

Even if you trust your factory, skipping inspections is one of the fastest ways to face defective shipments. Think of inspections as your eyes and ears on the ground.

- Third-party inspections allow you to:

- Check raw materials before production begins

- Monitor production mid-way to catch errors early.

- Confirm finished products match agreed standards before shipping.

For example, an importer once placed an order for custom kitchenware. By arranging a mid-production inspection, the inspector found that the factory had swapped in a cheaper grade of steel without approval. Because the issue was caught early, the importer avoided a disastrous shipment.

This is how inspections save money, not add to your costs.

Step 4: Build in consistent product quality assurance

One inspection is not enough. Quality control works best when it is consistent.

- Here are proven ways to keep standards steady:

- Schedule periodic checks, not just at shipment.

- Use detailed checklists tailored to your product category.

- Keep communication with your factory active rather than reactive.

Remember, factories may change staff or suppliers of raw materials without notice. Consistent monitoring ensures these shifts don’t affect your final product.

Step 5: Be proactive about communication

- Practical ways to stay ahead:

- Weekly progress updates with photos or video calls

- Shared quality checklists that both sides update

- Using local agents or sourcing companies who speak the language and understand the culture

Step 6: Have a backup plan

Even with audits and inspections, things can go wrong. Shipping delays, sudden factory shutdowns, or unexpected labor shortages happen. The smart move is to prepare for this from the start.

- Work with at least two factories when possible.

- Diversify across regions to reduce risks from local issues.

- Build buffer time into your supply chain.

This way, a single disruption does not collapse your entire operation.

Real-world results: Importers who avoided major setbacks

One apparel importer shared that they once skipped a factory audit to save time. The first shipment looked fine, but the second arrived with over 40 percent defective stitching. After introducing third-party inspections and audits, their defect rate dropped below two percent.

Another importer of electronics required mid-line inspections. When a batch of components overheated during testing, the factory corrected the problem immediately instead of shipping the defective batch. This move saved thousands in returns and protected their reputation with retailers.

Stories like these prove that consistent product quality assurance is not just a process; it’s the difference between growth and loss.

Make quality control your edge

Avoiding quality control issues is not about luck. It is about systems. With factory audits, third-party inspections, written agreements, and consistent communication, you can avoid defective imports and keep your customers happy.

The real advantage comes when quality is not just checked, but expected at every stage. That’s when your supply chain becomes predictable, reliable, and built for long-term success.

Ready to Take Control of Your Supply Chain?

At Importivity, we specialize in helping importers avoid quality control issues before they become costly mistakes. Whether you need a factory audit, third-party inspections, or ongoing product quality assurance, our team is here to make sure your shipments arrive exactly as promised.

Contact Importivity today and secure consistent quality for every order.

frequently asked questions

Why are quality control issues so common with remote factories?

Because you are not on site daily, small changes in materials or processes can go unnoticed until products are shipped.

What is a factory audit, and why is it important?

A factory audit is an on-site review of the factory’s capacity, systems, and compliance. It helps ensure the factory can meet your product standards.

How do third-party inspections reduce risks?

They act as independent verification, checking that your products meet the agreed standards before shipping.

Can I rely only on the factory’s own quality control?

It’s risky. Factories may cut corners under pressure. Independent inspections ensure your expectations are consistently met.

How often should inspections take place?

Ideally, at three stages: before production begins, during production, and before shipment. Regular checks create consistent product quality assurance.