When businesses compare Nearshoring vs Offshoring, the discussion frequently revolves around two critical aspects: speed and quality. Every organization seeks faster delivery times and consistent quality, yet the sourcing and production strategy chosen can significantly influence both. While offshoring once appeared as the most cost-effective model, shifting global conditions have changed the equation. Consequently, many companies are now re-evaluating their supply chains to determine whether nearshoring could provide a more balanced solution.

In recent years, businesses have increasingly looked toward nearshore manufacturing in Mexico as a strategic alternative to overseas production. Simultaneously, they have become more aware of the numerous offshoring supply chain challenges that can impact their operations. If your business has ever faced delayed shipments or inconsistent product quality, you likely understand the importance of this comparison.

Understanding Nearshoring vs Offshoring at a Glance

To simplify the discussion, consider a side-by-side comparison of both sourcing strategies. Nearshoring vs Offshoring differs mainly in terms of proximity, communication, cost, and agility. Nearshoring refers to relocating production closer to the company’s home market, often in neighboring countries such as Mexico. Conversely, offshoring involves outsourcing production to distant regions, typically in Asia, to capitalize on lower labor costs.

This distinction highlights why businesses today no longer view cost as the sole deciding factor. Instead, organizations are evaluating the complete picture, including total landed cost, flexibility, and risk exposure.

This comparison shows why businesses no longer see cost as the only deciding factor.

Lead Time Comparison on Nearshoring vs Offshoring

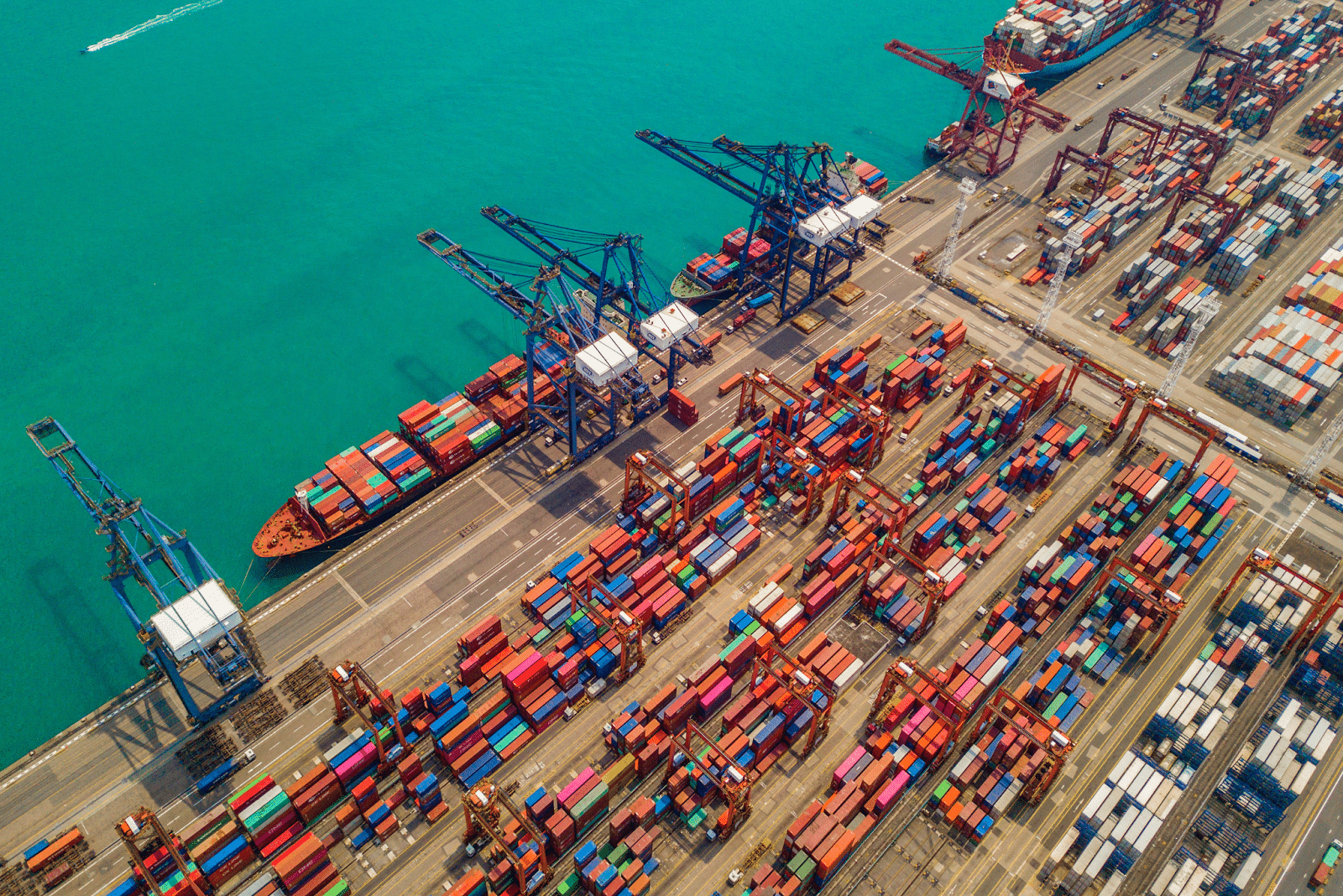

Lead time remains one of the most important factors influencing competitiveness in global supply chains. When companies opt for nearshore manufacturing in Mexico, transit time is often measured in days or weeks rather than months. As a result, businesses can quickly adjust production schedules when demand fluctuates or product changes are required. For instance, a U.S. company shifting production to Mexico can reduce delivery timelines by more than half compared to sourcing from Asia.

On the other hand, offshoring generally requires long-distance ocean freight. Between factory scheduling, maritime shipping routes, customs clearance, and inland transportation, it may take several months for goods to reach distribution centers. Moreover, any disruption, such as port congestion or geopolitical tension, can further extend those delays. Therefore, lead time advantages are one of the main reasons why companies are increasingly drawn toward nearshoring models.

Product Quality in Global Sourcing: Nearshoring vs Offshoring

Quality control represents another area where Nearshoring vs Offshoring decisions create a tangible impact. With nearshoring, maintaining quality becomes far easier due to geographical closeness. Production sites in Mexico enable quality engineers and managers to visit facilities regularly without requiring international flights or complex travel arrangements. This accessibility allows faster problem-solving, real-time oversight, and closer collaboration with manufacturing teams.

Conversely, offshoring introduces additional challenges. Time zone differences, cultural nuances, and language barriers can slow down communication and decision-making. Frequently, by the time quality issues are detected, products may already be in transit across oceans, leaving little opportunity for immediate correction. Consequently, many organizations find that the slight cost increase associated with nearshoring is justified when weighed against the risk of unusable or defective inventory.

Offshoring Supply Chain Challenges Affecting Global Businesses

Although offshoring initially appeared unbeatable due to its low labor costs, recent years have revealed a number of hidden complexities. Among the most pressing offshoring challenges are:

- Shipping delays resulting from global port congestion.

- Rising container costs that significantly reduce profit margins.

- Trade uncertainties and shifting tariff structures.

- Limited visibility across complex, multi-tiered supply chains.

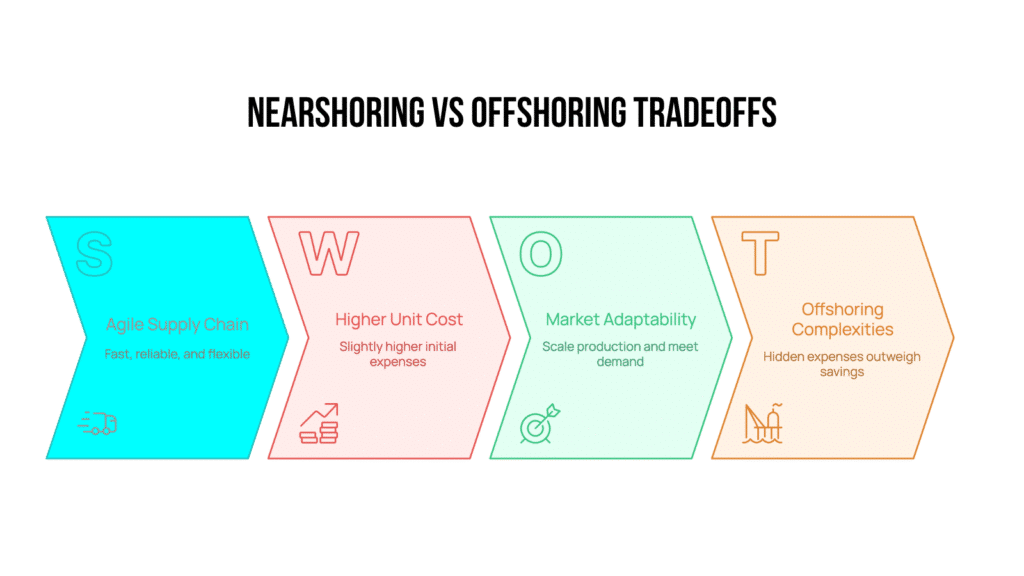

These factors collectively make offshoring less predictable than ever before. While offshore factories may continue to offer lower production costs on paper, the hidden expenses linked to shipping delays, lost quality control, and volatile logistics frequently outweigh the savings. Consequently, many global brands are now exploring nearshoring vs offshoring tradeoffs with renewed focus.

Why Businesses Are Reconsidering Nearshoring vs Offshoring Strategies

The growing appeal of nearshoring stems from its ability to balance cost efficiency, quality control, and supply chain resilience. Companies adopting nearshore models often collaborate with sourcing experts to simplify the transition. Specialized services like product sourcing and supplier vetting ensure compliance, negotiate competitive pricing, and maintain consistent output quality.

Additionally, reshoring and nearshoring solutions give companies the flexibility to move manufacturing closer to home without shouldering all associated risks. This hybrid approach enables organizations to maintain cost-effectiveness while enhancing visibility and agility throughout their operations.

The Role of Flexibility in Nearshoring vs Offshoring

Market volatility demands rapid adaptability. When a product gains sudden traction, nearshoring allows businesses to scale production quickly and meet market demand efficiently. Shorter supply chains facilitate faster replenishment, improved responsiveness, and better inventory control.

By contrast, offshoring remains less adaptable due to long lead times and communication gaps. When forecasts miss the mark, companies often face either costly overstock or frustrating stockouts. This lack of flexibility creates inefficiencies that directly impact profitability, prompting many decision-makers to reconsider the long-term sustainability of their offshore strategies.

Cost vs Value in Nearshoring vs Offshoring

While offshoring may appear more economical at first glance, total cost analysis often tells a different story. When calculating total landed cost, it is essential to include inventory carrying expenses, quality risks, and the cost of extended delivery cycles. Nearshoring, although slightly higher in unit cost, reduces these hidden risks and allows more frequent, smaller-batch shipments, ultimately improving cash flow and customer satisfaction.

Therefore, the modern conversation around Nearshoring vs Offshoring is not simply about reducing expenses but optimizing value. For companies that prioritize reliability, product quality, and operational speed, nearshoring often delivers a stronger return on investment in the long run.

The decision between Nearshoring vs Offshoring now extends beyond labor cost considerations. It encompasses speed, product quality, resilience, and overall supply chain agility. Nearshoring, especially in regions such as Mexico, offers faster lead times, improved oversight, and reduced risk exposure. Offshoring still presents cost advantages, yet those savings are frequently overshadowed by logistical and quality challenges.

Businesses that prioritize flexibility and reliability are increasingly viewing nearshoring as the smarter, more sustainable path forward.

Choosing the Right Strategy for Your Supply Chain

Ready to Reduce Lead Times and Improve Product Quality?

At Importivity, we simplify global sourcing decisions. Whether you are exploring nearshoring in Mexico or reassessing your existing offshore supply chain, our experts ensure your production strategy aligns with your goals for speed, quality, and profitability.

frequently asked questions

What is the biggest difference in lead time between Nearshoring vs Offshoring?

Nearshoring typically reduces delivery time to weeks, while offshoring may extend to several months because of longer shipping routes and customs procedures.

How does product quality differ between Nearshoring vs Offshoring?

Nearshoring facilitates regular oversight and rapid adjustments, whereas offshoring introduces distance and communication barriers that can compromise quality.

What are common offshoring supply chain challenges?

The most common include delays, high shipping costs, fluctuating tariffs, and limited transparency across global networks.

Why is nearshore manufacturing in Mexico gaining popularity?

Mexico offers proximity to the U.S., cultural alignment, cost competitiveness, and shorter transit times, making it ideal for North American businesses.

Is nearshoring always more expensive than offshoring?

While unit costs may be marginally higher, total costs often balance out once speed, flexibility, and reduced risk are considered.