When a business begins discussing an exclusive manufacturing agreement, it often feels like a significant milestone. Such an agreement signals that a supplier is ready to produce your product exclusively, offering what appears to be security through predictable pricing, consistent production, and a dependable partnership. However, beneath this appealing surface lies a reality that every business should approach with caution and preparation.

Exclusivity in manufacturing is a two-way street. Once you sign, you commit to a relationship that limits your flexibility to explore other suppliers, even when unexpected challenges arise. If your chosen manufacturer struggles with production capacity, fails to meet deadlines, or raises prices unexpectedly, you may find yourself with no easy alternatives. Therefore, before signing any binding contract, the real due diligence begins with the right questions—questions that will safeguard your business from costly mistakes hidden in the fine print.

Define What “Exclusive” Means in Your Manufacturing Agreement

Not every exclusive manufacturing agreement follows the same structure, and the term “exclusive” can have several interpretations depending on how it is outlined in your contract. Some agreements grant your supplier the sole right to manufacture your product globally, while others may only apply to specific product lines or geographic regions.

Before proceeding, ask your supplier for detailed clarification on the following points:

- Does exclusivity apply to all products or only specific SKUs?

- Is exclusivity limited to a particular country or region?

- Can you partner with another manufacturer if additional capacity is needed?

Having clear answers ensures you do not unintentionally restrict your business growth. Exclusivity can benefit both sides when terms are fair, but vague definitions often lead to restrictions that stunt scalability and innovation.

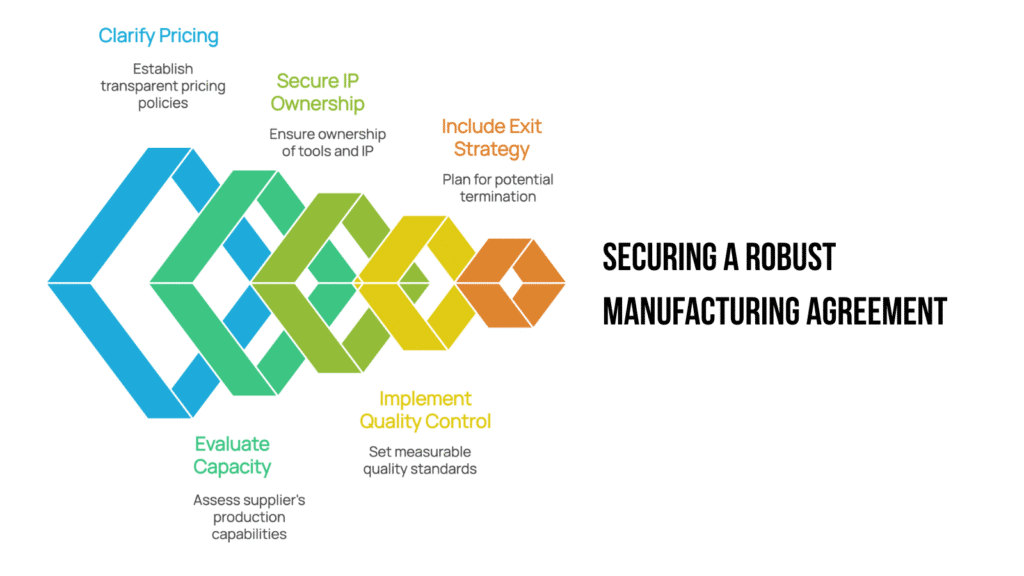

Clarify Pricing Transparency and Adjustment Policies

One of the most critical aspects of any exclusive manufacturing agreement involves long-term pricing structure. While an exclusive partnership can provide stability in production costs, it can also lock you into unfavorable terms if your supplier raises prices unexpectedly or without clear justification.

Ask your supplier:

- How will pricing be adjusted over time?

- Are material cost increases directly passed on to you?

- Is there a maximum cap on annual price increases?

Establishing transparent pricing rules upfront allows you to plan your budget confidently and prevents surprise cost escalations. Ideally, pricing adjustments should be tied to objective benchmarks, such as raw material indexes, instead of arbitrary decisions made by the supplier. This kind of transparency strengthens trust and ensures financial predictability throughout the partnership.

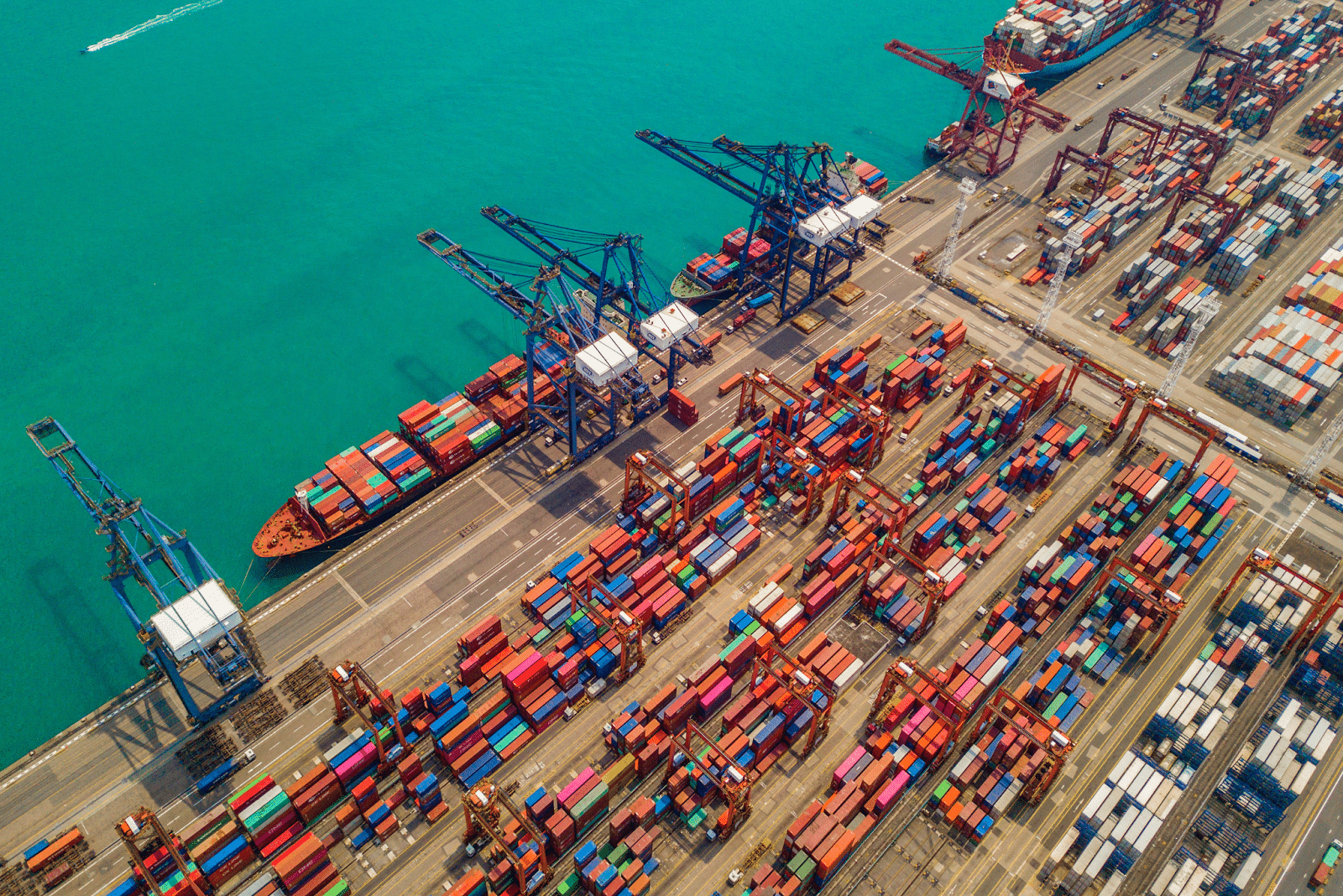

Evaluate Supplier Capacity and Contingency Planning

Every manufacturer, even the most experienced, faces production challenges. Therefore, your exclusive manufacturing agreement must include contingency planning to ensure your business doesn’t come to a standstill if problems arise.

Ask your supplier:

- What is the plant’s maximum output capacity?

- What are the lead times during peak periods?

- Are there backup facilities or partners for emergencies?

If your supplier hesitates or lacks backup plans, it’s a major red flag. True exclusivity should never mean vulnerability. Instead, it should balance commitment with resilience and flexibility.

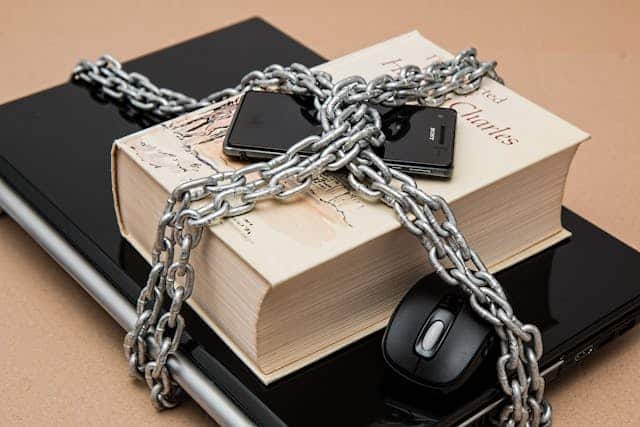

Secure Ownership of Tooling, Molds, and Intellectual Property

A crucial but often overlooked part of any exclusive manufacturing agreement is ownership of tooling and intellectual property (IP). Many disputes occur when manufacturers create molds, prototypes, or adjustments for a product and later claim partial ownership.

Key IP protection questions:

- Will I own the molds and tools if I change suppliers?

- Does the manufacturer hold any rights to my designs?

- How are design changes and prototypes documented?

Always ensure your agreement clearly states that you retain all IP and tooling ownership. This protects your brand from misuse, especially if the relationship ends.

Implement Strong Quality Control Standards

Quality is the foundation of every successful exclusive manufacturing agreement. Without firm quality control processes in writing, you risk being locked into a contract with inconsistent results.

Discuss quality management in detail:

- How frequently are quality checks conducted?

- Can I request third-party audits?

- What steps are taken if defect rates exceed acceptable limits?

Having measurable quality standards gives you leverage to enforce compliance and demand improvements when necessary. It also strengthens accountability between you and your manufacturer.

Include an Exit Strategy Before Signing

No matter how promising the partnership looks, every exclusive manufacturing agreement needs a clear exit plan. This clause ensures you can withdraw smoothly if circumstances change or performance declines.

Ask these critical questions:

- Under what conditions can the agreement be terminated?

- How much notice must be given before exiting?

- Are there any penalties or costs for early termination?

An exit strategy doesn’t mean anticipating failure, it means preparing for flexibility and safeguarding future business evolution.

When Exclusive Manufacturing Agreements Go Wrong

In real business scenarios, rushed exclusive manufacturing agreements have caused both setbacks and lessons. For example, one brand hurried into an agreement before a major trade show and soon faced doubled production times and unplanned cost increases. With no exit clause, they were locked in for two years, losing both money and market momentum.

Conversely, another company wisely added a clause allowing a secondary manufacturer to step in if deadlines were missed by over 30 days. When a machine breakdown caused delays, this clause protected their delivery timeline and client trust.

These examples highlight that a few well-structured clauses today can save years of financial and operational frustration.

Building Trust and Balance in an Exclusive Manufacturing Agreement

When carefully negotiated, an exclusive manufacturing agreement can foster loyalty, trust, and priority service from suppliers. The goal is not to avoid exclusivity but to structure it intelligently.

View your manufacturer as a strategic partner, one who values clarity as much as you do. Transparent communication, well-defined responsibilities, and mutual respect lead to stability, while ambiguity breeds misunderstanding and conflict.

Ask More, Regret Less

Committing to an exclusive manufacturing agreement should be a strategic decision grounded in clarity and confidence. Every question you ask before signing is an investment in your business’s security and scalability.

To summarize, always:

- Define the exact meaning of exclusivity.

- Clarify pricing mechanisms.

- Confirm capacity and backup options.

- Set clear quality control standards.

- Protect intellectual property.

- Include a balanced exit clause.

Your future supplier should welcome these questions; they prove that you value a transparent and mutually beneficial relationship.

Ready to explore reliable manufacturing partners? Check out our Made in USA Manufacturing Connections.

Your Exclusive Agreement Checklist

Partner with Importivity for Expert Guidance

At Importivity, we help businesses navigate the complexities of exclusive manufacturing agreements. Our team connects you with verified manufacturers both in the U.S. and globally, ensuring that your agreements are structured with fairness, flexibility, and long-term scalability in mind.

Whether you’re launching a new product line or expanding production, Importivity ensures that every contract detail supports your vision and protects your intellectual property.

frequently asked questions

What is an exclusive manufacturing agreement?

By lowering It’s a contract where a manufacturer agrees to produce your product exclusively, typically in exchange for guaranteed order volumes or pricing commitments.weight, reducing damage, and improving efficiency in container usage.

Why does exclusivity require extra caution?

Because exclusivity limits flexibility, making it vital to define terms that protect you from supply disruptions, pricing issues, or quality declines.

Can I still work with other suppliers?

In some cases, yes. If the contract allows exceptions for backup production or certain SKUs, you can maintain alternative options.

How can I protect my product design?

Ensure your agreement states that all tooling, molds, and intellectual property belong solely to you, preventing future ownership disputes.

What should an exit clause include?

It should clearly define notice periods, penalties (if any), and termination conditions that allow you to withdraw without heavy risk.