Whiskey Towers Manufacture Sourcing Case Study

How Importivity helped transform a concept into a premium stainless-steel dispenser through precise prototyping, overmolding, and optimized supply chain logistics, a true Manufacture Sourcing Case Study in efficiency and innovation.

The Vision Behind Whiskey Towers

Whiskey Towers wanted more than a dispenser; they envisioned a product that combines elegance, durability, and seamless functionality. They aimed to stand out in the hospitality and home bar market with a design that simplifies pouring, looks premium, and works reliably over time. In this manufacture sourcing case study, we took on prototyping, design optimization, overmolding techniques, quality control, and logistics to reduce complexity and avoid the common pitfalls many new product launches face.

Turning Rough Ideas into Refined Prototypes

When Whiskey Towers first approached Importivity, the idea existed mostly on sketches and rough drawings

From Sketches to CAD Models

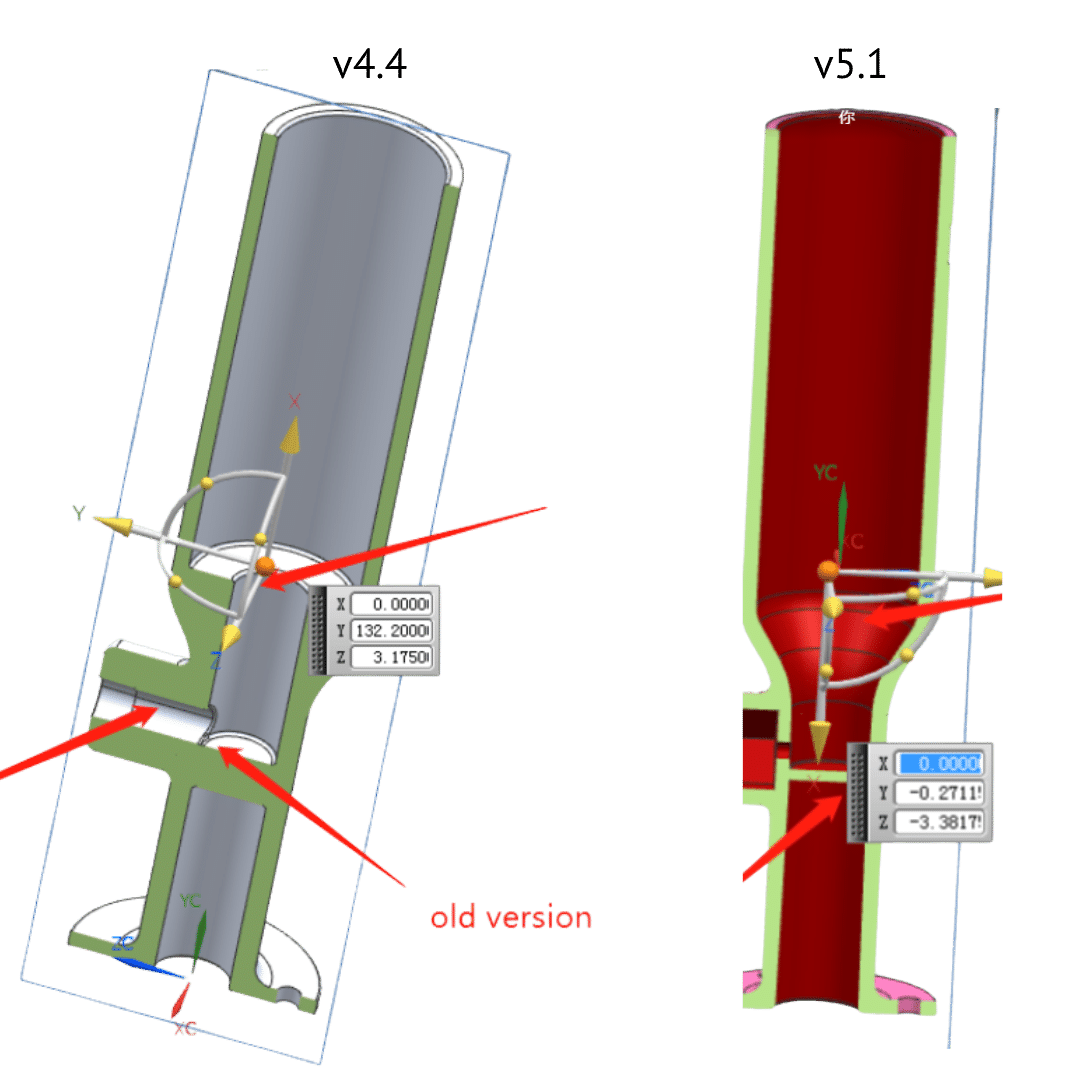

Whiskey Towers began with rough drawings. In this manufacture sourcing case study, Importivity transformed those sketches into precise CAD files, defining every curve, joint, and fitting for both performance and aesthetics.

Design Optimization

We refined the models to ensure overmolding tolerances, durability, and structural strength, so stainless-steel fittings integrated seamlessly with the plastic body.

Mold Development

Finalized mold drawings prepared factories for consistent, large-scale production without compromising on quality or design intent.

sUBMIT A SOURCING REQUEST UNDER 2 MINUTES

Verify your email and submit a sourcing request so we can quickly review your needs and start helping you find the right products or manufacturers.

Perfecting Overmolding & Pouring Performance

One of the biggest challenges in this manufacture sourcing case study was integrating a stainless-steel fitting securely into plastic without risk of leaks or weak joints. We tested multiple overmolding techniques and grommet sizes to ensure each unit poured smoothly, resisted wear, and preserved visual appeal.

Turning Rough Ideas into Refined Prototypes

When Whiskey Towers first approached us, their concept lived primarily on sketches and rough drawings. We began by dissecting the overall objectives, material constraints, and final use-cases. Then came CAD modeling, where our engineers brought the initial concept to life in digital form.

Initial Concepting

We captured every creative insight, from dispenser shape to the look of the embedded fitting.

CAD Drawing

Our design team translated hand-drawn sketches into precision CAD files, ensuring every angle and measurement matched industry best practices.

Optimization & Mold Drawing

After reviewing CAD mockups, we refined weak points and streamlined geometry. Our mold drawings accounted for overmolding tolerances crucial for embedding stainless steel within plastic.

Navigating Mass Production & Quality Control

Scaling production isn’t just making more units; it’s maintaining consistent quality.

- Material Consistency: Each batch of plastic resin and stainless steel met strict specs.

- Production Oversight: On-site factory validation to catch mold defects or weak overmolds early.

- Rigorous Testing: Random unit tests, leak checks, stress and visual inspections before packaging.

Sourcing Company Case Studies

Real examples of how our sourcing company delivers results across industries and markets.

Related Resources for Manufacture Sourcing

The strategies that powered this manufacture sourcing case study are the same ones you can apply to your own projects. Importivity provides a suite of free resources to help de-risk manufacturing, validate suppliers, and calculate costs before you commit.

BOM Template

Organize Prototype Components and Costs

Organize every component, from stainless-steel fittings to plastic bodies, with true cost visibility. In this case, it was essential to account for overmolding tolerances and packaging costs early in the design process.

RFQ Template

Standardize Supplier Quotes from Manufacturers

Standardize supplier outreach with a clear, detailed request. For projects like Whiskey Towers, this ensures every manufacturer quotes against the same requirements, making comparisons accurate and fair.

Factory Vetting Checklist

Validate Manufacturers On-Site

Evaluate whether a supplier has the capabilities for overmolding, CNC, and finishing before moving into production. This is how we identified factories able to meet Whiskey Towers’ strict quality standards.

Supplier Onboarding Checklist

Ensuring a Smooth Path from Prototype to Production

Streamline compliance documentation, QC standards, and payment terms when bringing a new factory into your supply chain. This helped Whiskey Towers transition smoothly from prototype runs to scalable production.

Product Sourcing Guide

Your Roadmap to Scalable and Reliable Manufacturing

A step-by-step framework to de-risk global trade, covering supplier vetting, prototyping, and cost management. Ideal for entrepreneurs looking to follow the same path Whiskey Towers took.

What This manufacture Sourcing Case Study Achieved

This manufacture sourcing case study highlights how an idea sketched on paper became a refined, scalable product ready for market.

Accelerate Product Development

Turned rough drawings into engineered CAD files, prototypes, and production-ready molds in record time.

Ensure Consistent Quality

Partnered only with vetted factories capable of meeting strict material, overmolding, and finishing standards.

Optimize Costs Despite Tariffs

Balanced stainless-steel precision with cost-effective plastic components, while reducing freight and packaging expenses.

Create New Revenue Opportunities

Developed a custom storage and presentation solution that not only protected the product but also drove upsells.

Build a Scalable Supply Chain

Transitioned from small-batch prototyping to full production runs with confidence in compliance, QC, and landed costs.

Logistical Excellence & Retail-Ready Presentation

In this manufacture sourcing case study, logistics and packaging were just as important as design.

Premium Brand Packaging

Developed protective packaging that not only safeguarded each dispenser but also conveyed Whiskey Towers’ upscale brand identity.

Cost-Efficient Shipping

Optimized box dimensions and pallet layouts to maximize container capacity, cutting freight costs per unit.

Streamlined Distribution

Coordinated warehousing and last-mile logistics to ensure reliable delivery to both retailers and direct customers.

Retail-Ready Presentation

Created shelf-ready designs with clear branding and easy unboxing, improving the in-store customer experience.

Frequently Asked Questions

If you need further assistance, feel free to reach out to our team!

What makes this a unique manufacture sourcing case study?

This manufacture sourcing case study highlights how Importivity transformed rough sketches into a mass-produced retail product by leveraging CAD modeling, mold optimization, packaging innovation, and global logistics. It shows end-to-end execution, not just factory matchmaking.

How did Importivity ensure Whiskey Towers’ prototypes were production-ready?

Our team converted initial sketches into precise CAD files, refined the designs for overmolding tolerances, and validated each prototype with small-batch runs. This approach ensured seamless scalability from concept to mass production.

Why is manufacturing sourcing different from simple product sourcing?

Manufacture sourcing goes beyond finding a supplier. It involves engineering refinement, prototyping, packaging design, and compliance management. For Whiskey Towers, we combined all these services to ensure their liquor dispensers were both production-ready and retail-ready.

What role did packaging play in this manufacture sourcing case study?

Packaging was a strategic advantage. We developed protective, brand-focused packaging that reduced freight costs and elevated in-store presentation. This positioned Whiskey Towers as a premium product while optimizing margins.

Why was China selected for Whiskey Towers’ manufacturing?

China’s advanced prototyping capabilities, supplier density, and competitive per-unit costs made it the logical choice. Even with tariffs, the speed-to-market and end-to-end production options ensured Whiskey Towers could scale profitably.

Can small businesses benefit from a manufacture sourcing approach?

Absolutely. This case study proves that even startups with only sketches can leverage a structured sourcing strategy. Our framework; including RFQ templates, BOM tracking, and factory vetting; reduces risk and accelerates growth for small businesses.

What measurable results did Whiskey Towers achieve through Importivity?

By partnering with Importivity, Whiskey Towers launched a premium product line with consistent quality, optimized packaging, faster distribution, and healthier margins. These results positioned them for long-term success in the retail and hospitality industries.

Still have questions?

Our team is happy to help! Visit our Help Center or contact us directly.