420seven Prototyping Case Study

This prototyping case study shows how Importivity navigated LED spectrum R&D, factory audits, and packaging innovations to help 420seven launch reliable, high-spec grow lights nationwide.

Why 420seven Needed a Prototyping Partner

This section explains the obstacles that made professional sourcing essential.

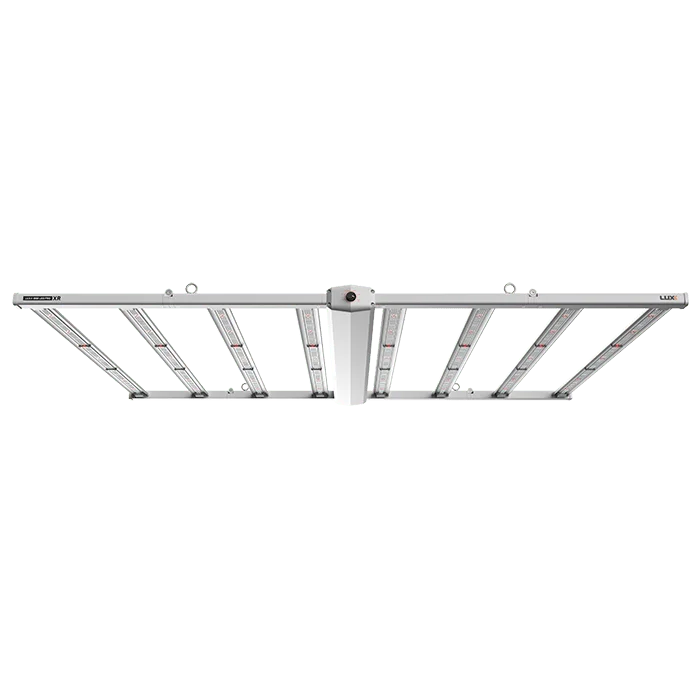

Engineering Precision for Growth Cycles

420seven needed exact LED spectrum calibration for both vegetative and flowering stages; critical for maximizing crop yields and building grower trust.

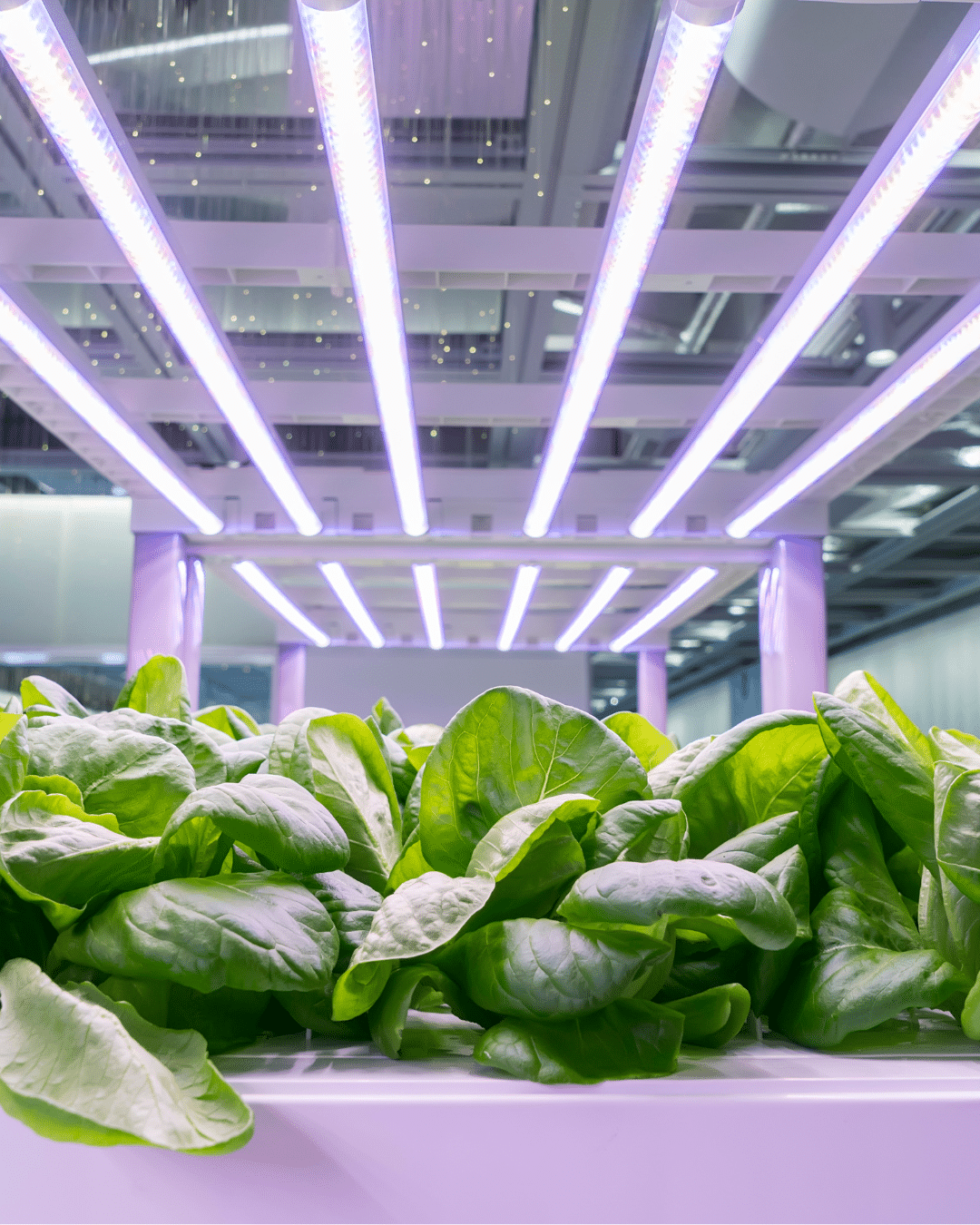

Durability in Harsh Agricultural Environments

Prototypes had to withstand heat, moisture, and exposure to corrosive chemicals without sacrificing performance or lifespan.

Scaling from Prototype to Mass Production

420seven required a clear path to scale… prototypes that could transition into full production runs with consistent quality, predictable costs, and efficient packaging for national distribution.

The Importivity Process

Importivity is not just another product sourcing company. Our process is built to remove uncertainty and protect margins at every stage. Here is how we make global sourcing predictable, transparent, and profitable:

Factory Audits and Supplier Vetting

We reviewed over 30 manufacturers to ensure technical capacity, quality standards, and compliance before starting prototype production.

1

LED Spectrum Testing and Product R&D

Importivity helped 420seven test 36 LED light spectra, optimizing performance for both vegetative and flowering growth cycles.

2

Solving Vulcanization Issues

By addressing diode degradation caused by agricultural chemicals, we developed durable, long-lasting prototypes that farmers could rely on.

3

Packaging and Logistics Optimization

Smart packaging design reduced freight costs while ensuring retail readiness and safe shipping from factory to distribution centers.

4

Want to start a prototyping project? Book A Call Now

sUBMIT A SOURCING REQUEST UNDER 2 MINUTES

Verify your email and submit a sourcing request so we can quickly review your needs and start helping you find the right products or manufacturers.

Sourcing Company Case Studies

Real examples of how our sourcing company delivers results across industries and markets.

Related Resources for Product Prototyping

The same tools that powered this prototyping case study are available free in our resources hub.

BOM Template

Organize Prototype Components and Costs

Every prototype is built from multiple parts, finishes, and processes. Our Bill of Materials (BOM) Template gives you a structured way to document each component, track costs, and forecast scaling expenses. This avoids hidden surprises later and ensures your prototype can realistically scale into full production.

RFQ Template

Standardize Supplier Quotes for Prototypes

During prototyping, you’ll often reach out to multiple factories for small test runs. Using a standardized RFQ (Request for Quote) Template ensures every supplier provides details in the same format covering specs, materials, MOQs, tooling, and timelines. This eliminates confusion, speeds up comparison, and helps you select the right prototype partner faster.

Factory Vetting Checklist

Validate Prototype Suppliers On-Site

Not all suppliers can handle the jump from a small prototype batch to full-volume production. With our Factory Visit Checklist, you can confirm equipment capacity, quality standards, and compliance before moving forward. This is especially critical in prototyping, where small mistakes can multiply into major costs.

Landed Cost Calculator

See the True Cost of Your Prototype

Prototypes often look cheap upfront, but international shipping, tariffs, and packaging can double the real price. Our Landed Cost Calculator lets you calculate the true per-unit cost from factory floor to your door, so you know exactly what your prototype costs and whether it’s viable at scale.

What This Prototyping Case Study Achieved

Faster time-to-market, lower landed costs, and durable prototypes gave 420seven a competitive edge in agricultural lighting.

- Launched in under 9 months. 50% faster than industry average.

- Reduced packaging and freight costs by more than 20%.

- Delivered consistent, lab-verified light performance.

- Built supply chain systems designed for scale.

How Importivity 420seven Go From Prototype to Mass production

Faster time-to-market, lower landed costs, and durable prototypes gave 420seven a competitive edge in agricultural lighting.

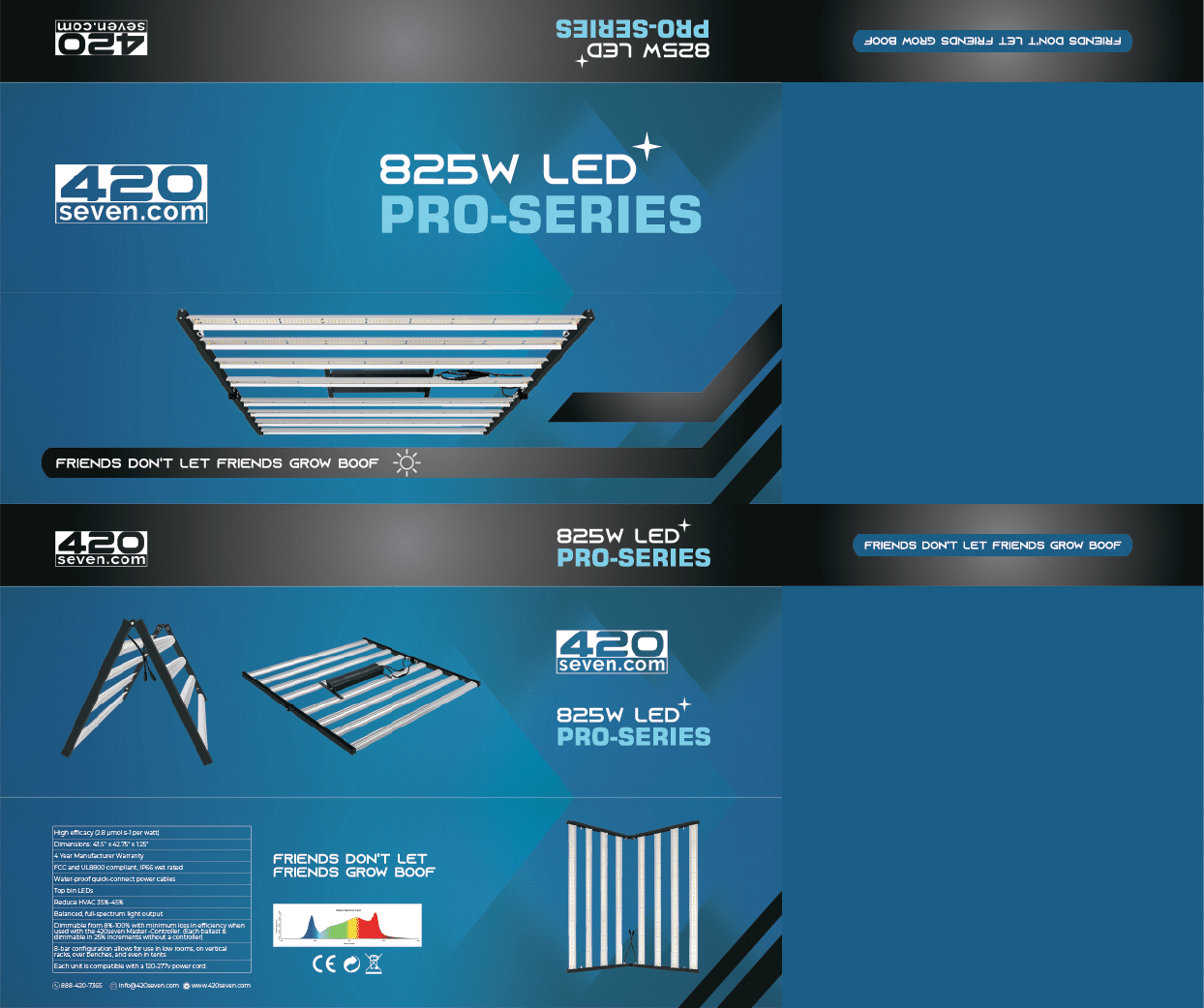

Packaging Designed for Protection & Scale

We engineered custom packaging that shielded sensitive LED prototypes from moisture, vibration, and shipping stress. The design also optimized carton sizes to reduce freight costs and ensured packaging could scale seamlessly into full production.

Branded Collateral that Builds Trust

Importivity helped 420seven create professional marketing materials, including quick-start guides, product inserts, and care instructions, that made every prototype look and feel like a retail-ready product. This elevated their brand and built confidence with early customers.

Seamless Warranty & Customer Registration

Each delivery included easy-to-use warranty registration cards that directed buyers online. This not only reassured customers but also captured valuable data, helping 420seven build stronger client relationships and plan long-term support.

A Complete Customer Experience from Day One

Instead of shipping bare prototypes, we delivered a full customer experience: packaging, marketing collateral, and registration tools. This holistic approach positioned 420seven as a polished, reliable brand ready for national distribution long before mass production began.

Why China is the Global Hub for Rapid Prototyping

China is the global hub for rapid prototyping because it combines unparalleled supplier networks, advanced manufacturing capabilities, and cost-efficient iteration within a single, highly developed ecosystem. Businesses like 420seven benefit from access to specialized components such as LED diodes and housings in days rather than weeks, alongside factories offering CNC machining, injection molding, and PCB assembly under one roof to slash lead times. Competitive pricing makes it possible to test multiple prototype versions without breaking budgets, while China’s logistics infrastructure ensures products move quickly from design to delivery, giving companies a vital first-mover advantage. For brands looking to accelerate development, validate designs, and reduce risks, Importivity leverages its strong relationships in China to deliver the fastest, most reliable path to market.

Frequently Asked Questions

If you need further assistance, feel free to reach out to our team!

Why is China considered the best location for rapid prototyping?

China has unmatched supplier networks, advanced prototyping capabilities like CNC machining and injection molding, and cost-efficient pricing that allows for fast iteration. Combined with established logistics, it helps businesses move from design to market in record time.

How did Importivity help 420seven with prototyping?

Importivity guided 420seven through every step from engineering LED spectrum outputs to designing scalable builds, managing quality control, and coordinating logistics. This ensured their prototypes were not only functional but production-ready.

What role did packaging and marketing materials play in this project?

We didn’t stop at the prototype. Importivity helped 420seven design custom packaging and create marketing materials, including warranty registration inserts, to ensure a professional, ready-for-market product launch.

How can resources like the RFQ Template and BOM Template support prototyping projects?

Tools such as our RFQ Template standardize supplier quotes, the BOM Template organizes prototype components and costs, and the Factory Visit Checklist ensures suppliers meet standards. These resources give businesses a clearer, more controlled prototyping process.

Can Importivity help my business with prototyping, even if I’m not in the agricultural tech space?

Absolutely. While 420seven was a high-tech agricultural lighting project, our expertise spans plastics, metals, textiles, and electronics. We adapt our sourcing and prototyping strategies to fit your industry and product type.

What challenges did 420seven face before working with Importivity?

Like many startups, 420seven struggled with unclear landed costs, unreliable suppliers, and the difficulty of scaling prototypes into production-ready models. Importivity solved these issues by providing vetted factories, transparent pricing, and a roadmap from prototype to mass production.

How does this prototyping case study apply to other industries?

The lessons from 420seven include but are not limited to rapid iteration, strict quality control, and efficient logistics; apply to any industry where speed and reliability matter. Whether you’re developing consumer electronics, apparel, or industrial components, Importivity’s process ensures prototypes evolve seamlessly into scalable products.

Still have questions?

Our team is happy to help! Visit our Help Center or contact us directly.