Rapid Prototyping Services

From feasibility analysis to production-ready prototypes, Importivity delivers high-quality results in days, not months. Our expert engineers, global factory network, and proven track record give you the speed, precision, and support you need to outpace competitors and get to market first.

Rapid Prototyping That Turns Ideas Into Market-Ready Products

Great ideas are only valuable when they reach the market. At Importivity, we specialize in rapid prototyping that eliminates the long delays, bloated costs, and missteps that hold businesses back. Whether you’re refining a new consumer product, developing advanced electronics, or testing industrial designs, we handle every stage from feasibility analysis and digital drawings to functional prototypes and mass production. With our team managing the process end-to-end, you get results faster, reduce risks, and stay ahead of competitors.

The Complete Rapid Prototyping Journey

Get your prototype moving today. Talk to a rapid prototyping expert.

Step By Step Process

- Feasibility Analysis

- Prove the concept before you invest

- Engineers review the idea, technical requirements, and market fit...

- Risk screen

- Cost drivers

- Path to market

- Feasibility memo

- Requirements brief

- Digital Drawings

- Turn sketches into precise CAD files

- Engineering grade CAD and renderings...

- CAD models

- Dielines

- Tolerance stacks

- Drawing pack

- BOM draft

- Basic Functionality Prototype

- Build fast, test fast, learn fast

- First working unit to validate core functions...

- Rapid build

- User feedback

- Change log

- P1 prototype

- Test notes

- Real World Sample

- From concept to something you can hold

- High fidelity sample that looks and feels like the final product.

- Fit & finish

- Packaging check

- Demo ready

- P2 sample

- Stakeholder demo

- Iteration and Testing

- Perfect through cycles

- Multiple rounds of refinement until issues are resolved...

- A/B trials

- Compliance checks

- Revision control

- Test reports

- Final spec set

- Prototype to Mass Production

- Where most firms stop we keep going

- Manufacturing transition handled end to end...

- Factory sourcing

- POs & SLAs

- QA/QC at scale

- Pilot run

- Production release

- Gate outputs include feasibility docs, CAD pack, prototypes, test notes, compliance documentation, and a production release kit.

sUBMIT A SOURCING REQUEST UNDER 2 MINUTES

Verify your email and submit a sourcing request so we can quickly review your needs and start helping you find the right products or manufacturers.

The Shenzhen Rapid Prototyping Advantage

Our on-the-ground team in Shenzhen’s Futian District gives clients direct access to the world’s fastest rapid prototyping ecosystem. In this hub, PCB suppliers, CNC shops, and assembly experts operate side by side, allowing us to build and test complex electronic prototypes in less than 48 hours; work that can take months in the U.S. This speed, combined with lower upfront costs and the ability to iterate quickly, means you get to market faster, cut risk, and stay ahead of competitors.

Why Choose Importivity for Rapid Prototyping?

Stop waiting. Start building. Contact Importivity for rapid prototyping today.

Premium Service Without the Premium Price

Enjoy white-glove support at a fraction of McKinsey-style costs.

1

Lightning-Fast Delivery

Get your prototypes in days, not months.

2

From Idea to Full Production

We handle everything from feasibility to mass manufacturing.

3

Quality Assurance and Quality Control (QA/QC)

Proven Results Across Industries

4

Revolutionizing Agricultural Tech Case Study

How a prototype became an industry innovation.

- LoRaWAN

- BLE

- Wi-Fi

- ESP32

- Capacitive moisture sensors

- ML calibration

- Shenzhen prototyping

- The Challenge

Indoor grower needed irrigation automation that scaled without monthly sensor recalibration.

- Market sensors required recalibration every 30 days, driving downtime and churn

- Client needed a step change in reliability, not a small tweak

- Build Speed

Shenzhen rapid prototyping shaved months off development.

48 hrs

Boards + housings

~3 mo

Typical U.S. timeline

60×

Calibration interval

5 yrs

Stable calibration

- Prototype Architecture

A sensor-control system with long-range telemetry and edge processing.

- LoRaWAN for long-range, low-power field data

- BLE for local device management

- Wi-Fi modules for cloud sync and dashboards

- ESP32 control panel for edge computing

- Capacitive soil moisture with ML calibration models

- Industry Impact

- Client scaled production and captured significant precision-ag market share

- New benchmark for sensor durability and IoT-driven irrigation

- Competitors re-engineered devices, advancing the category

- From Prototype to Standard

By combining a modern wireless stack with edge computing and ML-assisted calibration, the prototype moved from proof-of-concept to a durable, scalable platform that set a new bar for agricultural automation.

Sourcing Company Case Studies

Real examples of how our sourcing company delivers results across industries and markets.

Frequently Asked Questions

If you need further assistance, feel free to reach out to our team!

What is rapid prototyping and why is it important?

Rapid prototyping is the process of quickly designing, building, and testing product models before moving to mass production. It reduces risk, saves money, and speeds up time to market by allowing multiple iterations until the design is perfected. Importivity specializes in turning ideas into functional prototypes fast, often in days instead of months.

How fast can Importivity deliver a rapid prototype?

With our team in Shenzhen’s Futian District, we’ve delivered complex electronics prototypes in under 48 hours. In the U.S., the same project might take 8–12 weeks. Speed is our advantage, and we use it to help you beat competitors to market.

What industries benefit most from rapid prototyping?

We support plastics, metals, textiles, and electronics, but rapid prototyping is especially critical for electronics and consumer goods where speed, precision, and design iterations make or break a launch.

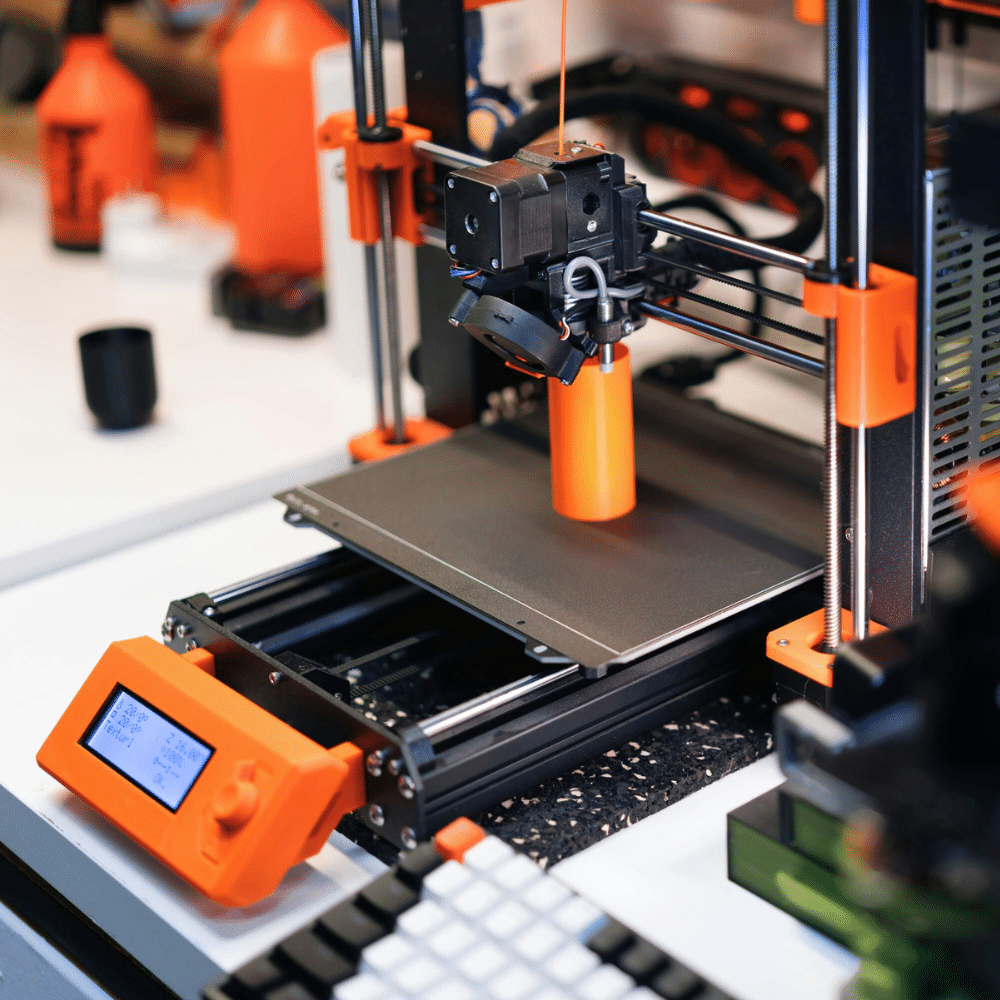

What technologies do you use in the prototyping process?

Depending on the project, we leverage 3D CAD software, CNC machining, PCB design, 3D printing, and wireless IoT components. For example, in 2020 we built an advanced agricultural sensor system using wireless protocols and custom control panels, creating industry-shifting results.

How is Importivity’s rapid prototyping different from competitors?

Unlike firms that hand off your project halfway, Importivity manages the entire process, from feasibility analysis and digital drawings to QA/QC and mass production. We combine U.S. business standards with on-the-ground teams in Asia, giving you white-glove service at unmatched speed and cost efficiency.

Can Importivity help with both hardware and packaging prototypes?

Yes. We design and deliver functional product prototypes as well as custom packaging prototypes that meet regulatory standards (FDA, CE, barcodes, etc.) while creating shelf appeal. We make sure your product and its packaging are ready for scale.

How do you ensure prototype quality before mass production?

We run multi-stage quality checks, from digital design validation to physical testing under real-world conditions. Only when a prototype meets strict performance benchmarks do we move forward with production. This avoids costly errors and delays later.

Do you handle the transition from prototype to mass production?

Absolutely. Once your prototype is finalized, our manufacturing management team takes over, securing vetted factories, negotiating contracts, ensuring compliance, and managing logistics. You don’t just get a prototype; you get a clear path to scale.

Can rapid prototyping help reduce tariffs and supply chain risks?

Yes. By testing and iterating prototypes in Vietnam, Mexico, or the U.S., we help clients diversify away from China when tariffs or trade risks threaten margins. Our “Plan B” sourcing strategies keep your supply chain tariff-resilient.

How do I start a rapid prototyping project with Importivity?

It’s simple… share your concept (even a sketch on a napkin), and our engineers will begin feasibility analysis. We’ll then provide a transparent plan, prototype timeline, and cost estimate. You can start today by contacting our team or submitting a sourcing request form.

Still have questions?

Our team is happy to help! Visit our Help Center or contact us directly.