Importing products can help your business grow fast. However, without proper checks, it can lead to expensive quality control mistakes. These errors can cause financial losses, customer complaints, and shipment delays.

At Importivity, we help businesses manage import risks and maintain product quality. In this guide, we’ll cover the most common quality control mistakes and show you how to avoid them.

1. Skipping Pre-Shipment Inspections

Why Are Pre-Shipment Inspections Important?

Pre-shipment inspections help ensure your products meet quality standards before shipping. They also reduce the risk of defects and unhappy customers.

How to Avoid This Quality Control Mistake

- Hire a Third-Party Inspector: Get a trusted inspection company to check your goods before shipment.

- Set Clear Inspection Standards: Define what quality, size, packaging, and materials you expect to receive.

- Review Reports Carefully: Approve shipments only after you review and confirm inspection results.

Example:

A company importing electronics once skipped pre-shipment checks. Later, they discovered faulty wiring. A simple inspection could have prevented recalls and refunds.

2. Failing to Define Quality Standards Clearly

Why Clear Standards Are Important

Vague communication often leads to poor-quality products. Manufacturers might use different materials or production methods than you expect.

How to Avoid This Quality Control Mistake

- Provide Detailed Specs: Include all materials, colors, measurements, and tolerances.

- Share Samples: Use approved samples to show exact expectations.

- Create a Quality Agreement: Set clear quality terms and define penalties for non-compliance.

Example:

A clothing importer asked for cotton shirts but received polyester ones. The confusion happened because material details were unclear.

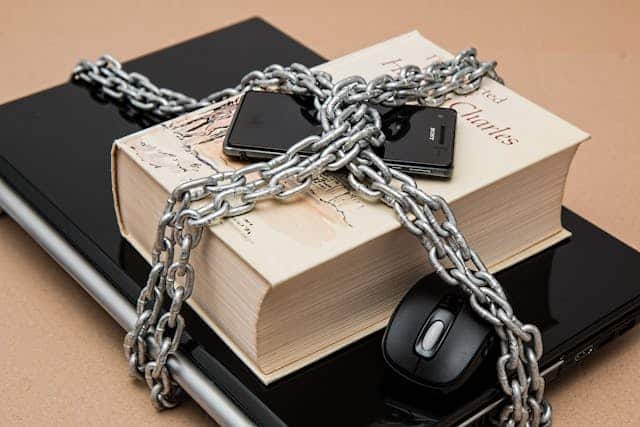

3. Ignoring Compliance and Certification Rules

Why Compliance Is Critical

Non-compliant products can be seized or fined. Worse, they can harm your reputation and delay shipments.

How to Avoid This Quality Control Mistake

- Check Regulatory Requirements: Research labeling, safety, and environmental laws for your market.

- Request Certifications: Make sure your supplier has CE, FCC, or FDA certificates if required.

- Do Lab Tests: Use third-party labs to verify product safety and compliance.

Example:

A toy importer faced huge losses when customs seized products containing banned chemicals. Compliance checks would have saved the shipment.

4. Not Monitoring Production Regularly

Why Continuous Monitoring Helps

Checking only the final product can hide issues that appear during production. Regular checks catch problems early.

How to Avoid This Quality Control Mistake

- Do In-Process Inspections: Inspect at different production stages.

- Conduct Factory Audits: Ensure ethical and consistent manufacturing practices.

- Test Random Samples: Pull random items for quality tests during production.

Example:

A furniture importer received weak chairs due to poor assembly. Routine checks could have fixed the issue earlier.

5. Choosing the Cheapest Supplier Without Vetting

Why Vetting Your Supplier Matters

Low prices can lead to low quality. Cheap suppliers may skip safety checks, use poor materials, or ignore regulations.

How to Avoid This Quality Control Mistake

- Perform Supplier Audits: Visit or review factory conditions and past work.

- Ask for References: Talk to other clients about their experiences.

- Start Small: Place a small order to test supplier reliability before bulk buying.

Example:

An importer switched to a cheaper supplier. Soon after, they faced high return rates and lost customers.

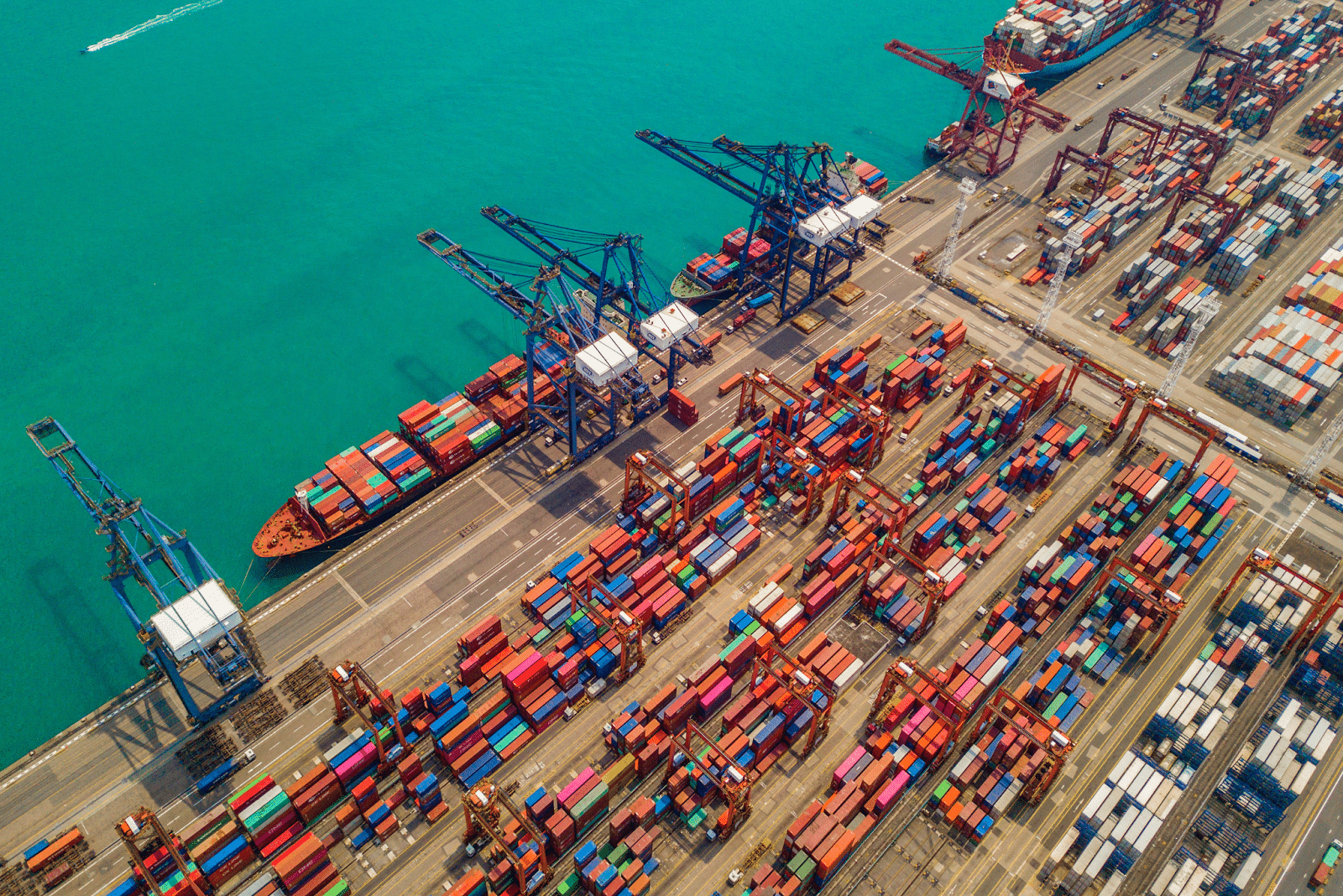

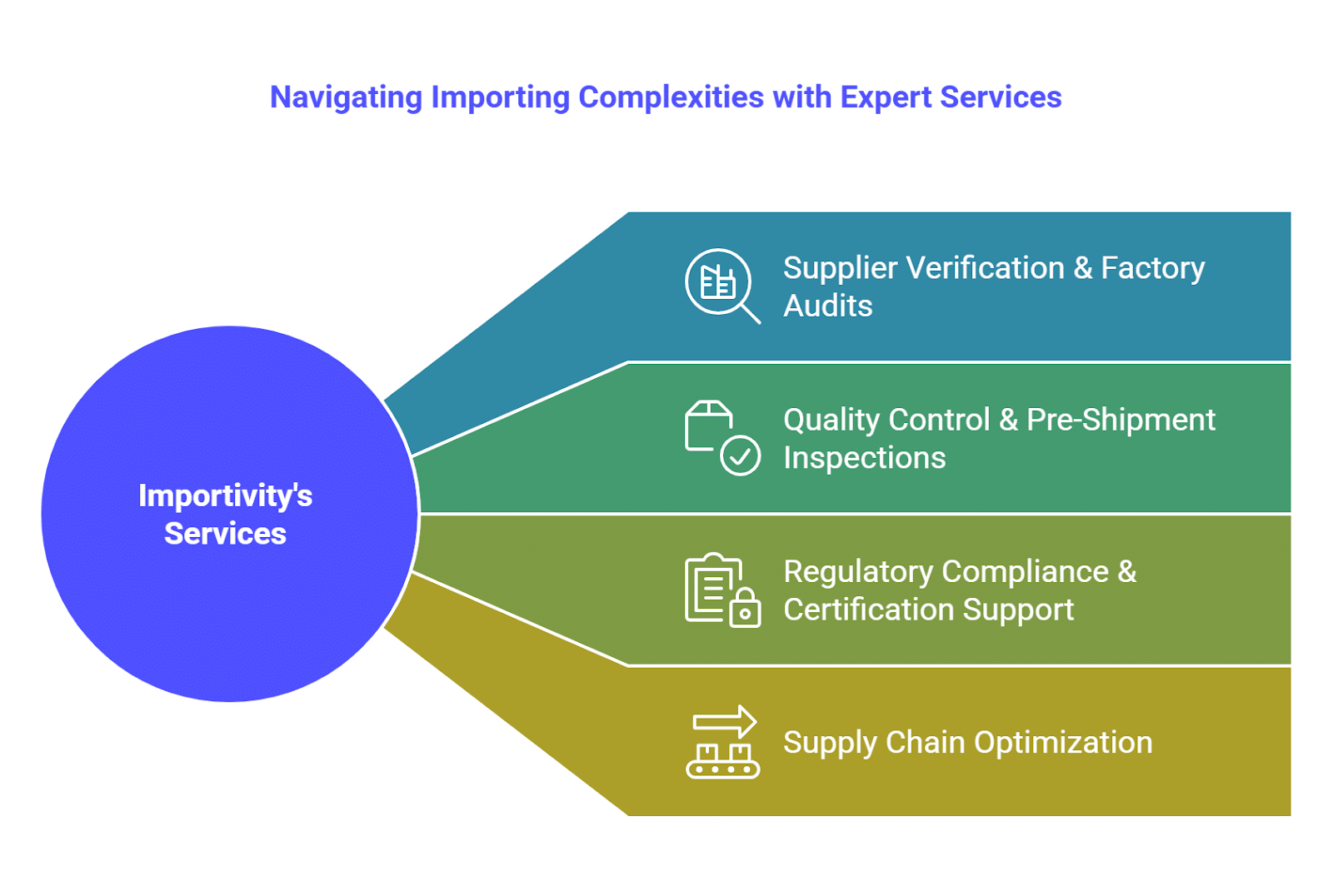

How Importivity Can Help You Avoid Quality Control Mistakes

At Importivity, we make importing easier and safer for your business. Our team helps you minimize risks and keep your supply chain strong.

- Supplier Verification & Factory Audits – We help assess potential suppliers before you commit.

- Quality Control & Pre-Shipment Inspections – We coordinate third-party inspections to ensure product quality.

- Regulatory Compliance & Certification Support – We assist in securing the necessary documentation and compliance testing.

- Supply Chain Optimization – We streamline processes to minimize risks and improve efficiency.

With our help, you can import confidently and avoid costly quality control mistakes.

Takeaways

Preventing quality control mistakes protects your profits and your brand. Always:

- Conduct pre-shipment inspections.

- Set clear product standards.

- Ensure full compliance.

- Monitor production closely.

- Vet suppliers carefully.

By following these steps, you’ll avoid expensive setbacks and deliver high-quality products every time.

frequently asked questions

What are the most common quality control mistakes in importing?

The most common mistakes include skipping inspections, unclear standards, and choosing unreliable suppliers.

How can I ensure my supplier meets quality expectations?

Conduct factory audits, set clear product specifications, request samples, and use third-party inspection services.

Why are pre-shipment inspections important?

They help detect defects early, saving you from expensive replacements or refunds.

What certifications should I check before importing goods?

Required certifications vary by industry but may include CE, FCC, FDA, or ISO compliance.

How does Importivity help businesses with quality control?

Importivity offers supplier verification, pre-shipment inspections, compliance support, and supply chain optimization to ensure smooth and reliable importing.